About ICARELIFE

One stop solution for worldwide OR builders

Who we are

reliable partner for OR Builder

ICARELIFE, a leading provider of innovative healthcare solutions, is dedicated to revolutionizing hospital hygiene control and ensuring the safety of healthcare professionals worldwide.”

ICARELIFE is a company that was established in 2019, specializing in the production and distribution of Powered Air Purified Respirators (PAPR). They have achieved significant success in the healthcare markets of Thailand and the Philippines. Through collaborations with SaintMed in Thailand and BIOSITE in the Philippines, ICARELIFE PAPR has captured the leading market share from 2020 to 2022. Additionally, their products have been sold in other European countries, expanding their reach beyond the ASEAN market.

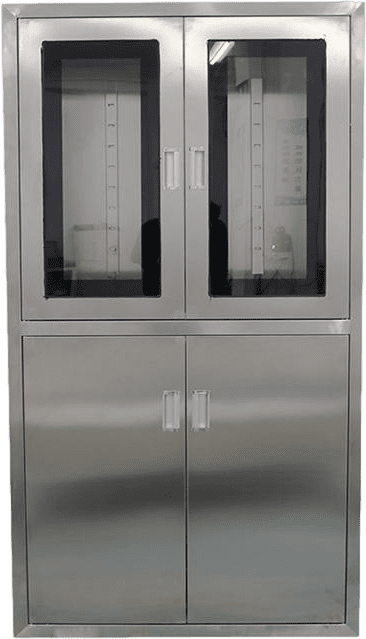

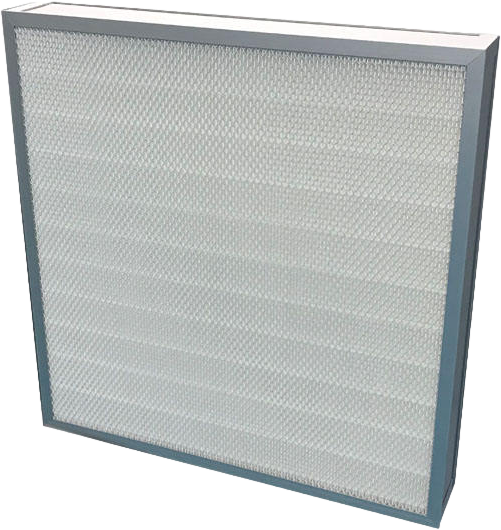

Building on their success in the PAPR market, ICARELIFE has shifted its focus to hospital hygiene control and air treatment, particularly in the field of Modular Operating Theater (MOT) equipment and supplies. They aim to provide their products and services to local operating room builders. Currently, ICARELIFE’s main business lines include OR control panels, hermetic doors, and scrub sink units.

Vision:

To become the globally recognized and trusted partner of choice for OR builders, delivering cutting-edge solutions that optimize hygiene standards, enhance efficiency, and elevate patient care.”

Mission:

Our mission is to continuously innovate and provide state-of-the-art solutions that create a hygienic and safe working environment for healthcare providers. We strive to exceed expectations, forge strong partnerships with our global network, and drive positive change in the healthcare industry.