What is a Laminar Flow Ceiling?

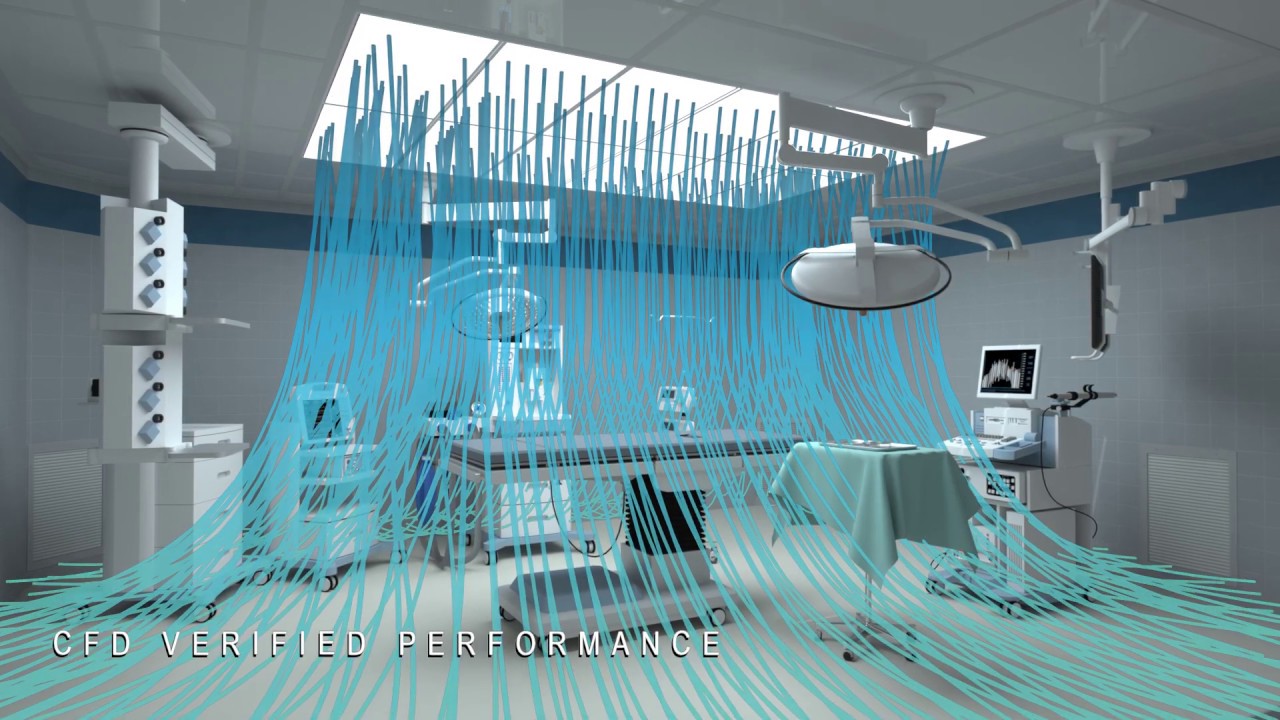

Design and Function: The system consists of a large air filter spanning the entire ceiling area under which sterile activities are performed. The purpose is to create a particle-free working environment by continuously flushing out air and airborne particles from the operating area.

Laminar Flow: The term ‘laminar flow’ refers to the smooth, orderly movement of air in parallel layers with minimal or no cross-over of streamlines. In contrast, ‘turbulent flow’ is chaotic and occurs when different air layers mix.

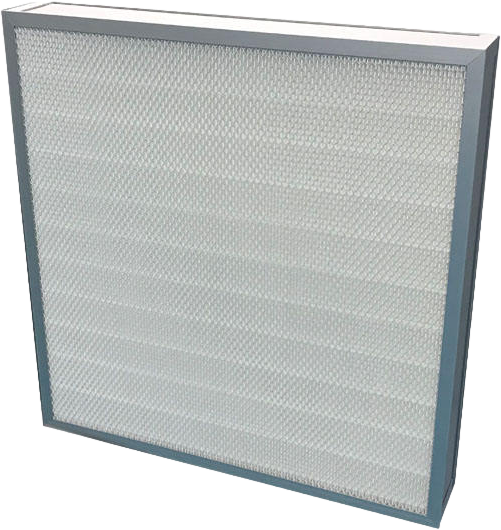

Air Filtration: Laminar Flow Ceilings use High-Efficiency Particulate Air (HEPA) filters, or in some cases Ultra Low Penetration Air (ULPA) filters, to capture minute particles that could be harmful. These filters remove more than 99.97% of particles larger than 0.3 micrometers, providing an exceptionally high degree of air purity.

Air Distribution: The purified air is then dispersed uniformly across the room, maintaining a constant flow of filtered air. This uniform distribution of air “sweeps” away particles and contaminants from the operating area, reducing the risk of infection.

The Necessity of Laminar Flow Ceilings

Minimizing Infection Risk

During surgical procedures, there is always a risk of infections caused by airborne particles and microbes. Laminar flow ceilings continuously flush out these contaminants from the air, significantly reducing the risk of post-surgical infections.

Maintaining Sterile Environment

They help in maintaining a high degree of sterility in the working area, which is particularly important in operating rooms, intensive care units, and pharmaceutical labs, where the presence of airborne particles can have severe consequences.

Regulatory Compliance

Many industries, such as healthcare and pharmaceuticals, have strict regulatory guidelines concerning air quality and sterility. Laminar flow ceilings are often a necessary component to comply with these guidelines and standards, such as those set forth by organizations like the FDA or WHO.

Enhanced Workflow

With a controlled environment, healthcare professionals can work more efficiently without worrying about contamination or infection risks. This can also lead to better patient outcomes.

Working Principle of Laminar Flow Ceilings

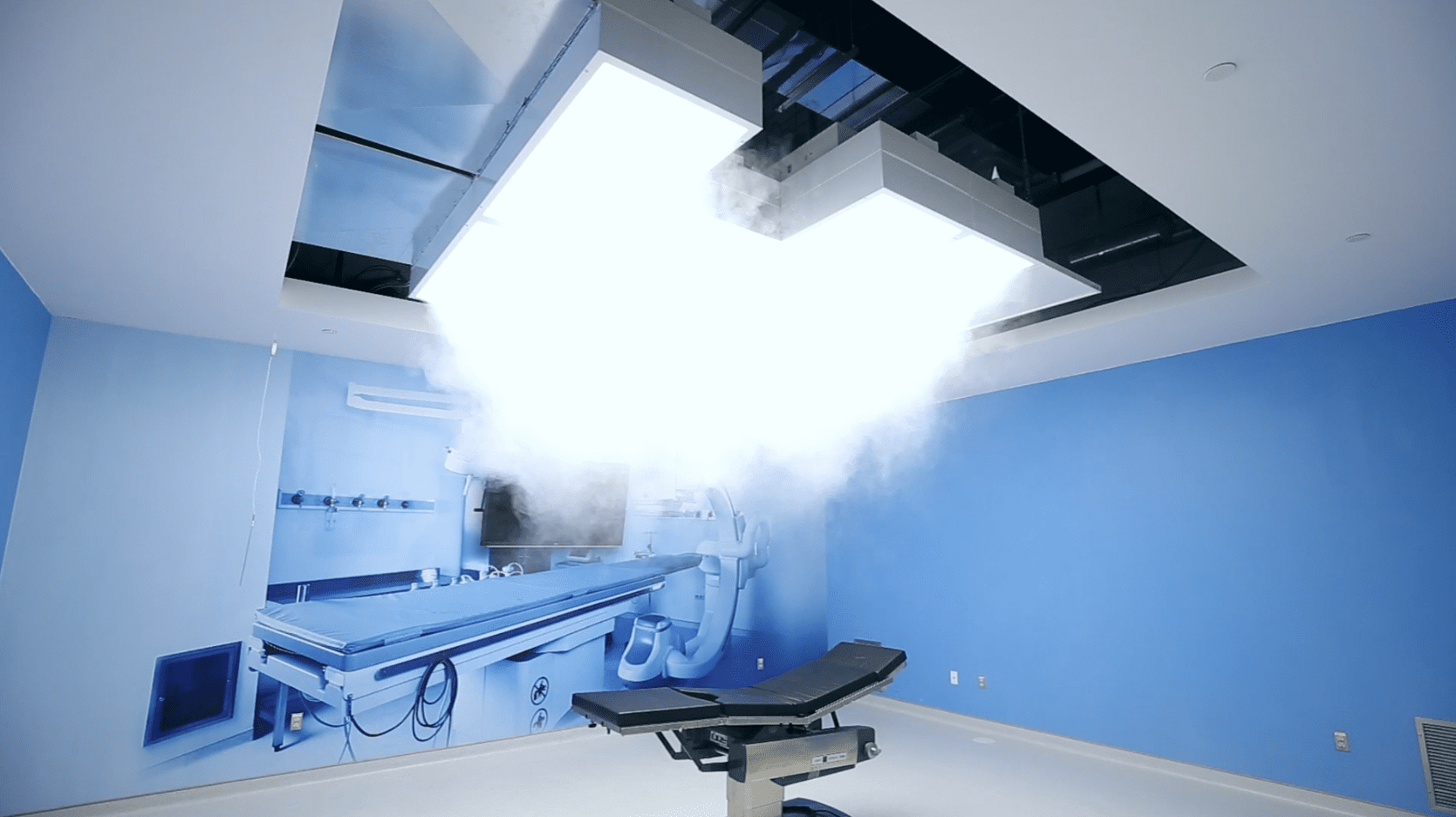

- Air Drawing

Initially, air is drawn into the laminar flow ceiling system from the surrounding environment. This is done through an inlet, which usually has a pre-filter to eliminate larger particles.

- Filtration

The drawn air is then passed through a highly efficient filter, typically a HEPA (High Efficiency Particulate Air) filter, or in some cases, an ULPA (Ultra Low Penetration Air) filter. These filters are designed to capture extremely small particles, often as small as 0.3 micrometers for HEPA and 0.12 micrometers for ULPA filters.

- Laminar Flow Creation

After filtration, the air is pushed downward in a controlled, unidirectional manner. This streamlined airflow is the “laminar flow”. The air moves at the same speed and in the same direction, allowing it to “sweep” away any particulates or contaminants that may be in the environment.

- Constant Circulation

The system constantly draws in new air, filters it, and then pushes it into the room. This constant circulation helps maintain a clean and sterile environment by continuously flushing out potential contaminants.

Benefits and Usage of Ceiling Laminar Airflow

Prevention of Contamination: The main benefit of a laminar flow ceiling is the prevention of contamination. The constant, unidirectional flow of filtered air “sweeps” away any airborne particles or contaminants, thereby reducing the risk of contamination.

Increased Sterility in Surgical Procedures: Laminar flow ceilings are particularly useful in operating rooms where they can help to prevent surgical site infections. By providing a constant flow of sterile air over the operating table, they create an environment that minimally contributes to potential infections.

Versatility in Clean Environments: Apart from operating rooms, laminar flow ceilings are used in a wide range of applications that require clean environments, including laboratories, pharmaceutical manufacturing facilities, and electronics manufacturing facilities.

Improved Product Quality: In manufacturing settings, particularly in the pharmaceutical, medical device, and electronics industries, laminar flow ceilings can help improve product quality by reducing the risk of product contamination during the manufacturing process.

Compliance with Regulations: Many industries have strict regulations regarding cleanliness and sterility. Using laminar flow ceilings can help facilities comply with these regulations and maintain the necessary certifications.

Energy Efficiency: Laminar flow ceilings provide efficient air circulation, which can contribute to energy savings in the long term by reducing the need for high-capacity HVAC systems to maintain the cleanliness and temperature of the environment.

Selecting the Right Laminar Flow Ceiling

- Understanding Your Requirements

The first step is to fully understand the needs of your application. For example, the requirements for a surgical operating room may differ from those of a pharmaceutical manufacturing lab.

- Space Constraints

Consider the dimensions of your room. The laminar flow ceiling needs to fit well within the available space.

- Airflow Type

Laminar flow can be vertical or horizontal. Vertical laminar flow is typically used in operating rooms to prevent contamination of the surgical site, while horizontal laminar flow may be used in certain laboratories or manufacturing environments.

- Filter Type

Laminar flow ceilings typically use HEPA (High-Efficiency Particulate Air) filters, which can trap particles as small as 0.3 microns. Some applications may require ULPA (Ultra Low Penetration Air) filters, which can capture even smaller particles.

- Compliance Standards

The laminar flow ceiling must meet the relevant regulatory standards for your industry. For example, in healthcare settings, the system may need to comply with specific ISO (International Organization for Standardization) standards or other regional healthcare regulations.

Get in touch

Ready to Elevate Your Product Range?

Our comprehensive line of ceiling laminar airflow is designed to help you expand your offerings and meet your clients’ needs more effectively. With swift delivery times, diverse product categories, and unwavering after-sales service, we are committed to fostering a robust business relationship. Contact us today to discover more about our products and services, and see how we can help enhance your B2B operations.

Request a Quote for Ceiling Laminar Airflow

Seeking a quote for our ceiling laminair airflow? Fill out the form below and our team will reach out to you promptly to discuss your specific requirements.