The Ultimate Guide to Operating Theater Wall Systems: HPL vs. Stainless Steel

Selecting the wall cladding for a modular operating theater is more than an aesthetic choice—it is a decision that impacts infection control, radiation shielding, fire safety, and the structural longevity of the healthcare facility. As hospitals shift toward modular construction to reduce on-site timelines, the debate between High-Pressure Laminate (HPL) and Stainless Steel (SS) has become a central focus for EPC (Engineering, Procurement, and Construction) firms worldwide.

Table of Contents

- 1. The Evolution of the Aseptic Shell

- 2. Deep Dive: High-Pressure Laminate (HPL)

- 3. Deep Dive: Stainless Steel (SS304/SS316)

- 4. Technical Performance Comparison

- 5. Installation and Integration Mechanics

- 6. The Healing Environment: Aesthetics & Psychology

- 7. Regulatory Compliance (ISO, HTM, DIN)

- 8. Cost-Benefit and Lifecycle Analysis

- 9. Summary: Selection Logic

- 10. Conclusion & Technical Support

1. The Evolution of the Aseptic Shell

The “Aseptic Shell” is the core of any controlled surgical environment. Historically, hospital walls were constructed using traditional masonry finished with specialized antimicrobial paint. However, these systems often failed due to cracking and the inability to maintain airtight seals under positive pressure.

Modern modular theaters utilize prefabricated panels that create a seamless, non-shedding, and airtight envelope. We believe the choice between HPL and Stainless Steel should be dictated by the specific clinical discipline and the mechanical demands of the theater.

2. Deep Dive: High-Pressure Laminate (HPL)

HPL, often referred to as Solid Grade Laminate (SGL), is a high-density material (approx. 1350 kg/m³) composed of multiple layers of kraft paper impregnated with phenolic resin, topped with a decorative layer and a protective overlay.

The Formica® Advantage

At ICARELIFE, we frequently utilize Formica® HPL. Modern HPL panels are engineered with silver-ion technology integrated into the surface. This ensures that the material actively inhibits the growth of bacteria and fungi—a critical factor in reducing Surgical Site Infections (SSIs). Its unique manufacturing process ensures the panels are completely non-porous and resistant to moisture, making them ideal for high-humidity surgical environments.

3. Deep Dive: Stainless Steel (SS304/SS316)

Stainless steel remains a cornerstone of healthcare infrastructure due to its perceived “purity” and extreme mechanical strength. It is inherently non-combustible, making it a primary choice in facilities where local building codes demand a Class A1 fire rating for wall cladding.

SS304 vs. SS316

For standard operating rooms, SS304 with a satin (brushed) finish is the industry standard. However, for specialty suites where aggressive saline solutions or heavy chemical disinfectants are used, we recommend SS316 for its superior molybdenum content, which prevents pitting and corrosion.

4. Technical Performance Comparison

| Technical Metric | HPL (Solid Grade) | Stainless Steel (SS304) |

|---|---|---|

| Surface Hardness | Exceptional (Resists scratches) | Moderate (Prone to visible scratching) |

| Impact Recovery | Elastic (Absorbs impact) | Plastic (May dent permanently) |

| VHP Resistance | High (Tested for 500+ cycles) | Excellent (Inert to VHP) |

| Fire Rating | Class B-s1, d0 (Typically) | Class A1 (Non-combustible) |

| Weight | ~14 kg/m² (10mm thickness) | ~16-20 kg/m² (with backing) |

Vaporized Hydrogen Peroxide (VHP) Compatibility

In 2026, VHP sterilization has become standard for terminal cleaning. Both materials perform well, but HPL must be specifically “medical grade” to ensure the resins do not yellow or degrade over time. Our HPL solutions are rigorously tested to withstand high-concentration H₂O₂ cycles without surface oxidation.

Acoustic and Thermal Insulation

A quiet operating room reduces surgeon fatigue. Modular HPL panels often incorporate a core of high-density Rockwool or Aluminum Honeycomb, providing sound reduction of up to 35dB-45dB, significantly higher than thin-gauge steel panels without specialized backing.

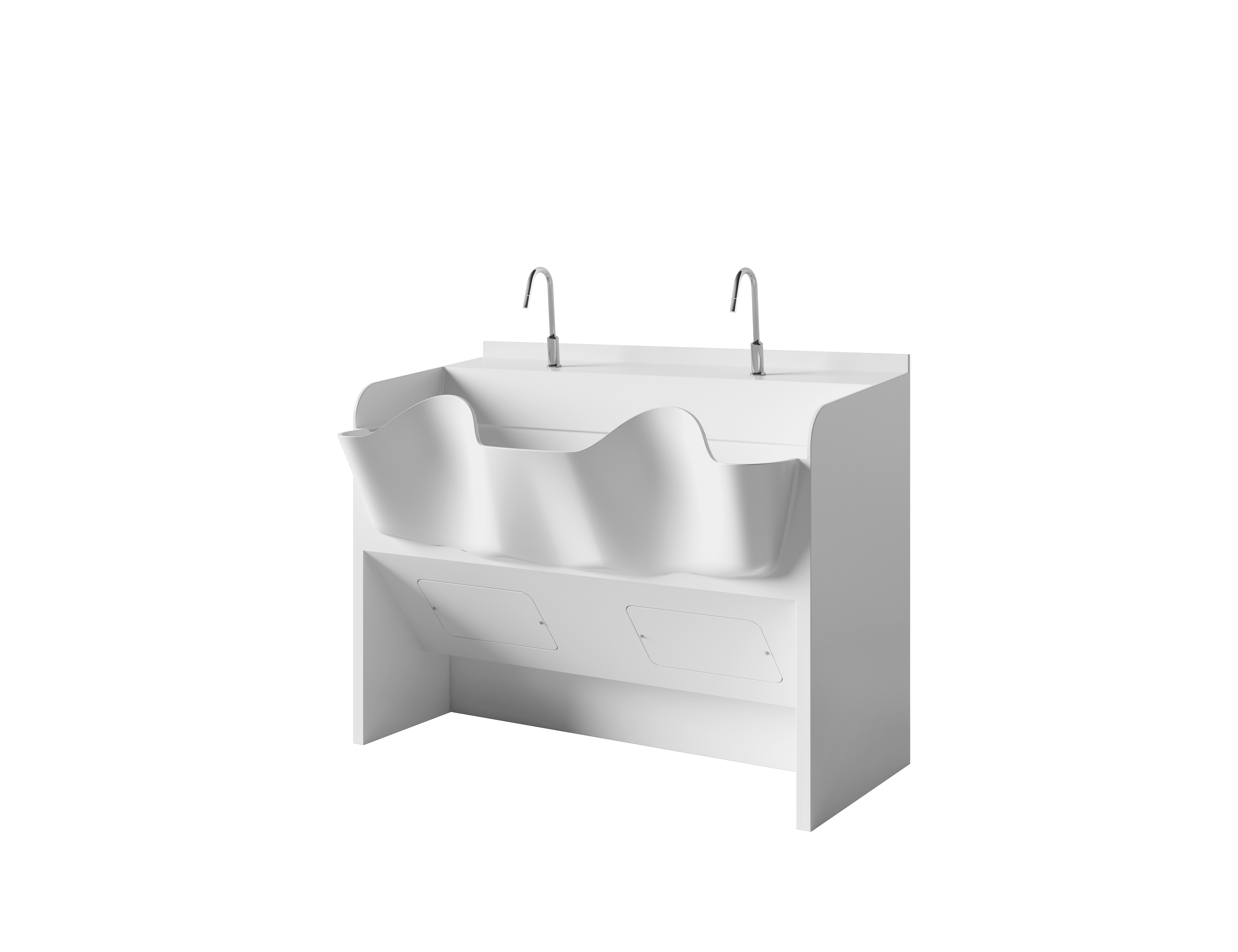

5. Installation and Integration Mechanics

The true value of a modular system lies in its sub-structure. We utilize a galvanized steel adjustable sub-frame that allows for precise leveling even if the base building walls are uneven. This system ensures that every panel is perfectly aligned for an airtight seal.

Lead Lining and Radiation Protection

In hybrid ORs or suites with C-arms, we integrate lead sheets (typically 1mm to 3mm) directly behind the wall panels. HPL is particularly easy to bond with lead lining, providing a seamless protective barrier without increasing the external footprint of the wall.

6. The Healing Environment: Aesthetics & Psychology

Clinical studies show that color therapy impacts both staff performance and patient recovery. Stainless steel can create a highly reflective, industrial environment that increases glare from surgical lights. In contrast, HPL offers a palette of over 200 colors and wood-grain finishes. By using soft greens or blues, we help hospitals create an environment that lowers the heart rate of patients and improves the focus of the surgical team.

7. Regulatory Compliance (ISO, HTM, DIN)

Every ICARELIFE wall system is designed to comply with rigorous international standards: ISO 14644-1 for particulate counts, HTM 03-01 for UK healthcare ventilation standards, and DIN 1946-4 for sterile integrity in clinical environments.

8. Cost-Benefit and Lifecycle Analysis

While Stainless Steel often carries a 15-25% higher initial material cost, its lifecycle can span 30+ years. However, HPL offers a faster Return on Investment (ROI) for modular projects due to lower shipping costs, reduced on-site labor (no welding required), and the ease of future modifications if new medical gas outlets need to be added.

Summary: Selection Logic

- Specify HPL if: You are prioritizing speed of installation, a modern aesthetic, and a cost-effective aseptic environment for general surgery or private clinics.

- Specify Stainless Steel if: You are designing a high-volume trauma center or a government facility where non-combustibility and “heavy-duty” standards are the priority.

10. Conclusion & Technical Support

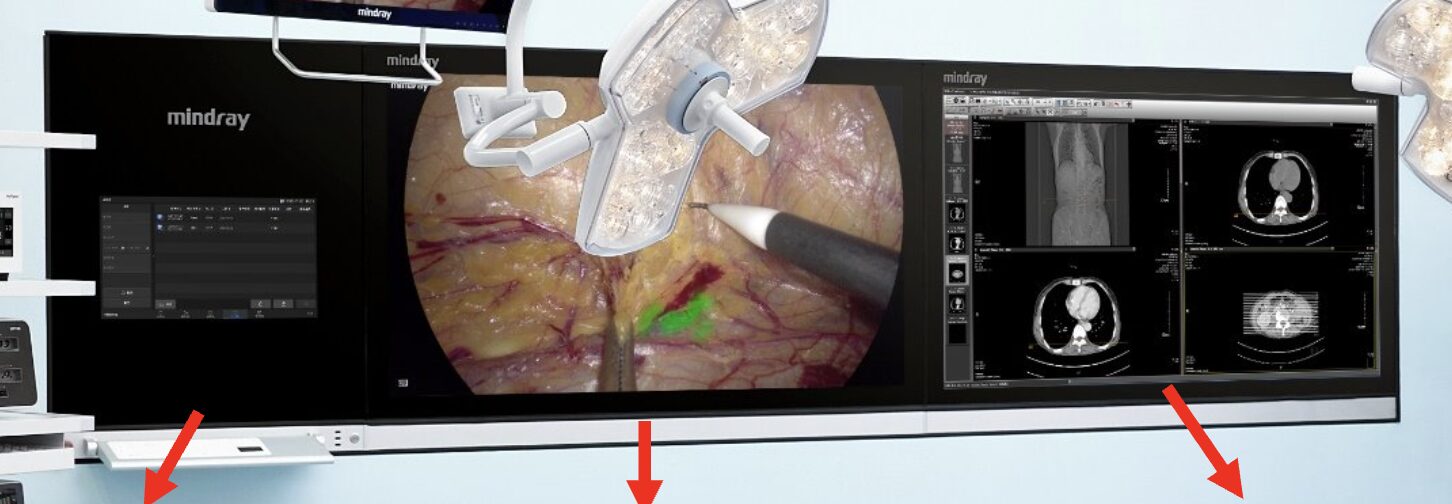

The “perfect” wall material doesn’t exist—only the right material for your specific clinical needs. At ICARELIFE, we don’t just supply panels; we provide the engineering oversight to ensure those panels integrate perfectly with your laminar ceilings, hermetic doors, and control systems.

Frequently Asked Questions

Q: Is HPL or Stainless Steel better for radiation shielding (X-Ray/CT)?

Both materials can be lead-lined. However, HPL is often preferred for Hybrid ORs because it is easier to bond with lead sheets during the manufacturing process, providing a seamless protective barrier.

Q: Do HPL panels meet Class A fire ratings?

Most medical-grade HPL panels are rated Class B-s1, d0. If your project specifically requires a Class A1 (non-combustible) rating, Stainless Steel is the mandatory choice.

Q: How do these materials handle Vaporized Hydrogen Peroxide (VHP)?

Both are VHP-resistant. We ensure our HPL panels use medical-grade resins that prevent yellowing during deep sterilization cycles.

Ready to Start Your Project?

Share a layout and list of components—We prepare a technical proposal within 24 hours.

Request a Proposal →© 2026 ICARELIFE. Precision Engineering for the Future of Surgery.