How to Install Modular Operating Theaters

1. Planning and Design

- Site Assessment: Conduct a detailed assessment of the location where the modular operating theater will be installed, ensuring compliance with medical regulations and requirements.

- Customized Design: Collaborate with architects and engineers to design the operating theater layout, including airflow, equipment placement, and space utilization.

- Materials Selection: Choose high-quality materials such as stainless steel panels, airtight doors, and medical control panels according to project requirements.

2. Preparing the Installation Site

- Clear the Area: Remove any existing structures or debris from the installation site.

- Leveling the Floor: Ensure that the floor is leveled and ready for the installation of modular components.

- Utility Connections: Prepare electrical, HVAC, and plumbing systems, ensuring that all required utilities are accessible at the installation site.

3. Installing the Structural Framework

- Wall Panel Installation: Begin with the installation of pre-fabricated wall panels, typically made from rust-resistant materials like stainless steel or insulated composite panels.

- Ceiling Systems: Install the modular ceiling panels with integrated laminar airflow systems to ensure sterile air distribution.

- Flooring: Apply antibacterial, non-slip flooring, ensuring a clean, sterile environment suitable for surgical operations.

4. Installing the Equipment

- Control Panels: Install operating room control panels, which manage lighting, airflow, and other key systems.

- Lighting Systems: Set up specialized surgical lights and general lighting for the room.

- Medical Gas Systems: Install outlets for oxygen, vacuum, and other medical gases as per design specifications.

- Doors: Fit airtight automatic or manual doors designed for operating rooms to ensure a sterile environment.

5. HVAC and Air Filtration

- Airflow System: Install laminar flow systems that provide filtered air to maintain sterility in the operating environment.

- Temperature and Humidity Control: Ensure that the HVAC system maintains optimal temperature and humidity levels for surgical procedures.

- Air Tightness: Ensure all seals and joints are properly installed to prevent contamination from external air sources.

6. Electrical and Plumbing Setup

- Power Supply: Install a reliable electrical system, including backup generators to ensure uninterrupted power supply during surgeries.

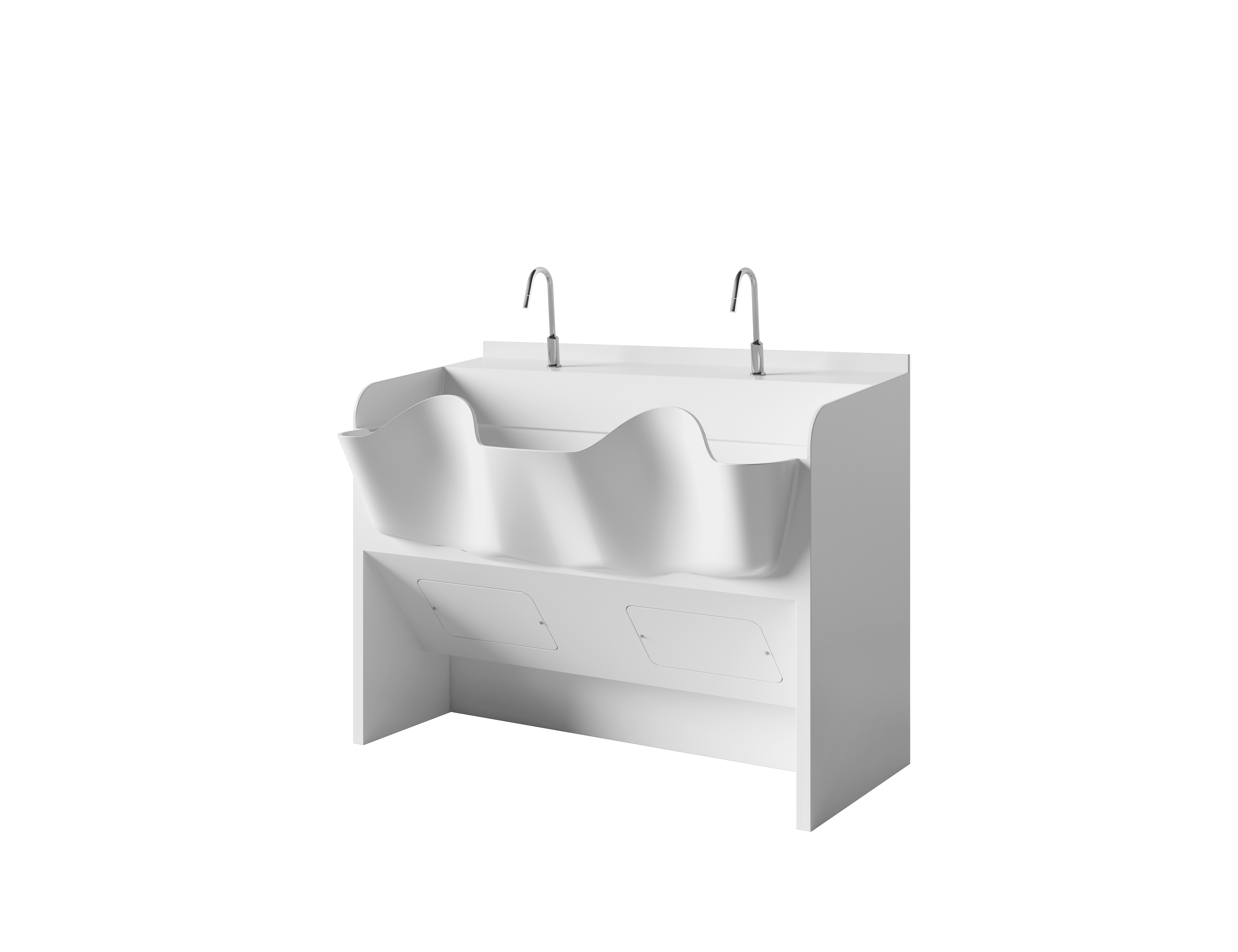

- Water and Drainage Systems: Connect the appropriate plumbing systems to medical sinks and sterilization equipment.

- Surge Protection: Ensure all electrical equipment has appropriate surge protection installed to avoid failures.

7. Installing Additional Features

- Storage Cabinets: Fit medical-grade stainless steel storage cabinets for sterile supplies and instruments.

- Surgical Scrub Sinks: Install high-quality stainless steel scrub sinks with hands-free operation for surgeons.

- Monitors and Communication Systems: Set up monitoring systems for vital signs and integrate communication systems for seamless interaction with other departments.

8. Testing and Commissioning

- System Testing: Test the functionality of all installed systems, including air filtration, lighting, medical gas, and electrical systems.

- Compliance Check: Ensure the operating theater complies with medical standards and local regulations for cleanliness, safety, and operational efficiency.

- Staff Training: Provide training to medical staff on how to operate the new equipment and use the modular theater effectively.

9. Final Inspection and Handover

- Quality Control Inspection: Conduct a thorough inspection of the installation to ensure all components are installed correctly and functioning as expected.

- Handover: Once all checks are complete, officially hand over the modular operating theater for use by medical personnel.