Modular Operating Theater vs. Traditional: Cost Comparison

Introduction

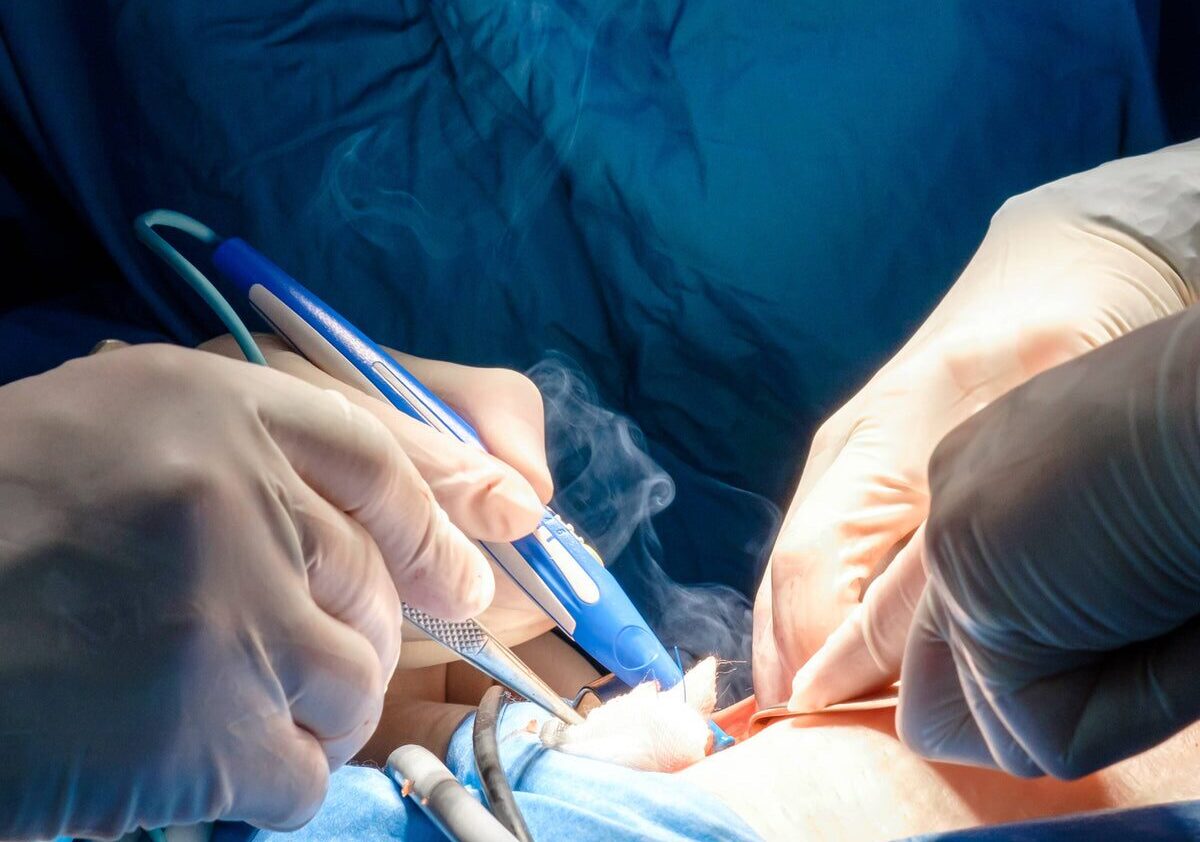

Operating rooms are the lifeblood of hospitals, generating 40–60% of revenue while under pressure to deliver cutting-edge care on tight budgets. With surgical demands rising—driven by aging populations and advanced procedures—hospitals in Thailand, the Philippines, and beyond need cost-effective, hygienic designs to stay competitive. Modular Operating Theaters provide a game-changing solution, offering prefabricated, scalable surgical environments that cut construction time by 30–50% and costs by 10–25% compared to Traditional Operating Theaters, which rely on labor-intensive, custom-built designs. As the global modular operating theater market heads toward $4.8 billion by 2030, efficiency and flexibility are critical. ICARELIFE, a leader in operating room control panels and hermetic doors, is transforming surgical spaces. This comparison explores construction, operational, and scalability costs, helping hospitals optimize budgets and performance in 2025.

Construction Costs: Modular vs. Traditional

Construction costs are a key consideration for Modular Operating Theaters versus Traditional Operating Theaters. Modular theaters, assembled off-site with prefabricated components, reduce expenses significantly. Data shows modular construction costs 10–25% less, averaging $200–$300 per square foot compared to $350–$500 for custom-built ORs. The streamlined process, using standardized designs and factory assembly, shortens timelines by 30–50%, often completing in 3–6 months versus 9–18 months for traditional builds. For example, a 600-square-foot modular OR might cost $120,000–$180,000, while a traditional one could exceed $300,000.

Traditional Operating Theaters, while offering tailored designs, face higher costs due to on-site labor, custom materials, and lengthy schedules. Complex HVAC systems and strict regulations drive up expenses. In fast-growing markets like Thailand and the Philippines, where rapid hospital expansions are vital, ICARELIFE’s modular solutions, including operating room control panels, deliver cost-effective quality.

Operational Costs: Efficiency and Maintenance

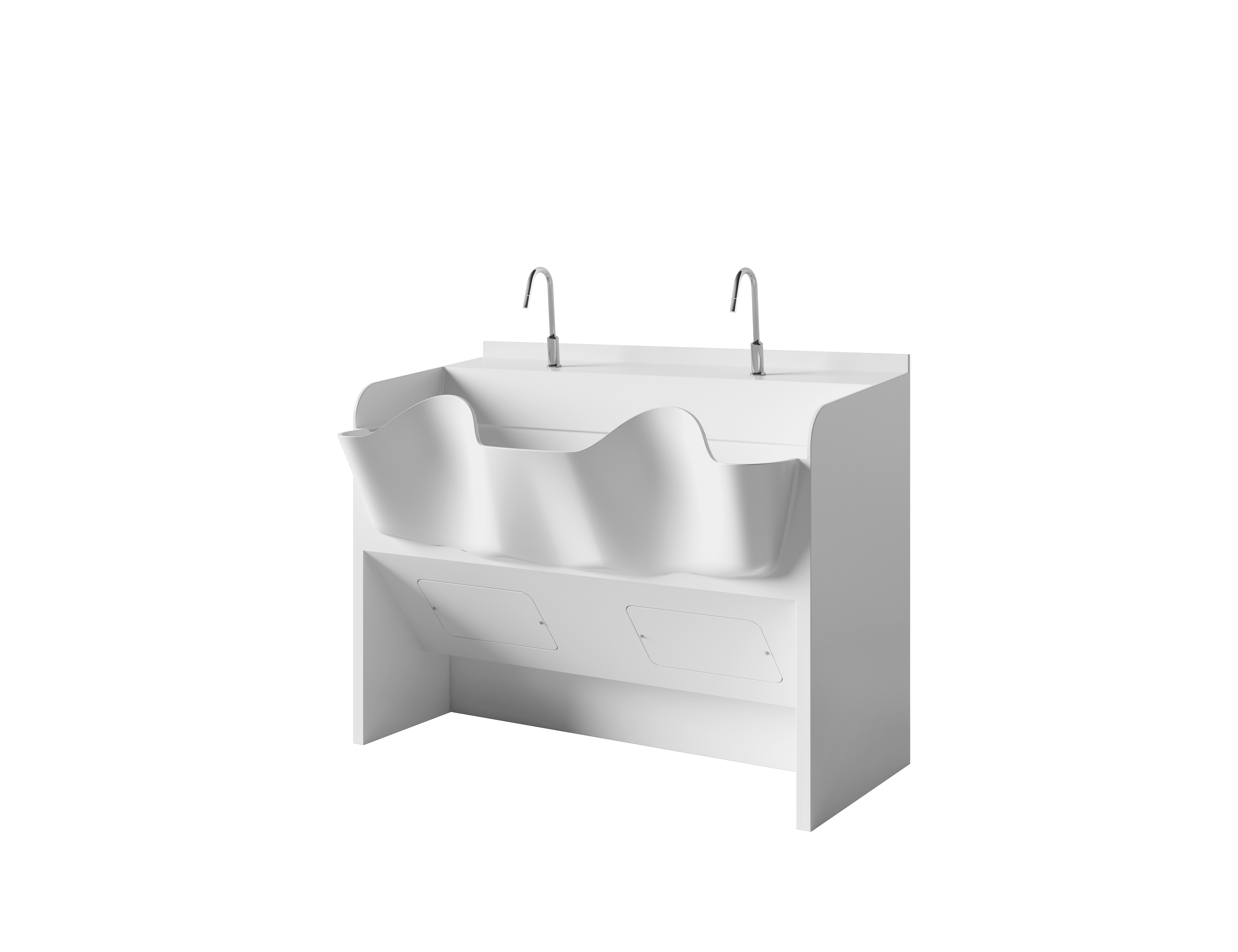

Operational costs are crucial for long-term OR sustainability. Modular Operating Theaters excel with seamless designs that simplify sterilization and lower maintenance. Smooth, non-porous surfaces and integrated systems, like ICARELIFE’s hermetic doors, reduce contamination risks, cutting cleaning time by up to 20%. Energy-efficient HVAC and lighting systems save 15–30% on utilities, with annual maintenance costs of $5,000–$10,000 versus $15,000–$25,000 for traditional setups.

Traditional Operating Theaters, with fixed, complex infrastructure, require costly maintenance. Custom HVAC systems need frequent servicing, and porous surfaces complicate sterilization, increasing labor expenses. Repairs cause downtime, disrupting surgical schedules and revenue. Modular theaters’ replaceable components minimize disruptions, and ICARELIFE’s hospital hygiene solutions ensure compliance with cleanroom standards, boosting efficiency.

Scalability and Flexibility: Future-Proofing ORs

Scalability sets Modular Operating Theaters apart. Designed for adaptability, modular ORs can be expanded or reconfigured at 50% lower cost than modifying traditional ORs, which often require extensive structural changes. For instance, a Philippines hospital upgraded its modular OR with ICARELIFE’s operating room control panel in under a month, compared to six months for a traditional retrofit. This flexibility supports evolving needs, like minimally invasive surgeries.

Traditional Operating Theaters, built as permanent fixtures, lack flexibility. Modifications cost over $100,000 for minor upgrades, and fixed designs struggle to adopt new technologies, reducing long-term value. As hospitals prioritize future-proofing, modular theaters’ scalability, championed by ICARELIFE, offers a strategic advantage.

Choosing the Right Solution: Your Decision Roadmap

Choosing between Modular Operating Theaters and Traditional Operating Theaters hinges on balancing cost, speed, and flexibility. Modular theaters offer advantages: 10–25% lower construction costs ($200–$300 per square foot), 30–50% faster builds (3–6 months), and 15–30% cheaper operational costs. Their scalability and hygienic designs, like ICARELIFE’s hermetic doors, suit growing hospitals in Thailand and the Philippines. Drawbacks include limited customization for specialized surgeries. Traditional theaters excel in bespoke layouts for complex procedures but face higher costs ($350–$500 per square foot), longer timelines (9–18 months), and inflexible designs.

Consider these factors:

- Budget: Modular theaters save 10–25% upfront and on maintenance, ideal for cost-conscious projects like Thailand hospital equipment. Traditional theaters require larger investments.

- Timeline: Modular’s 3–6-month builds fit urgent expansions in the Philippines; traditional builds take 9–18 months.

- Scalability: Modular upgrades cost 50% less, perfect for future growth.

Partner with experts like ICARELIFE, a leader in operating room control panels and hospital hygiene solutions. Their team tailors solutions to your budget and surgical needs, ensuring compliance and efficiency. Share this guide on LinkedIn or X to help others choose wisely, and contact ICARELIFE to build a future-ready OR in 2025.

Comparison: Modular vs. Traditional Operating Theaters

| Factor | Modular Operating Theater | Traditional Operating Theater |

|---|---|---|

| Construction Cost | $200–$300/sq.ft, 10–25% cheaper | $350–$500/sq.ft, higher due to custom materials |

| Timeline | 3–6 months, 30–50% faster | 9–18 months, labor-intensive |

| Operational Cost | $5,000–$10,000/year, 15–30% lower utilities | $15,000–$25,000/year, complex maintenance |

| Scalability | High: 50% cheaper upgrades, reconfigurable | Low: $100,000+ for modifications, fixed design |

| Customization | Limited: Standardized designs | High: Bespoke layouts for complex surgeries |

| Hygiene Compliance | Excellent: Seamless, non-porous surfaces (e.g., ICARELIFE’s hermetic doors) | Moderate: Porous surfaces complicate sterilization |

Table: Compare Modular Operating Theaters and Traditional Operating Theaters to choose the best cost-effective OR design for your hospital.

Keywords: Modular Operating Theater, Operating Room Control Panel, Hospital Hygiene Solutions, Traditional Operating Theater, ICARELIFE, Cost-Effective OR Design, Hermetic Doors, Thailand Hospital Equipment, Philippines Modular OR

Meta Description: Compare Modular Operating Theater vs. Traditional Operating Theater costs in 2025. Discover ICARELIFE’s modular solutions for cost-effective, hygienic ORs.