VOC Control in Modular Operating Rooms

Particle cleanliness is only half the story. This guide explains how to control VOCs, anesthetic gases, and surgical plume using molecular filtration, source capture, optimized ACH, low-emission materials, and airtight sealing—so modular OR projects can be commissioned with predictable results.

Why Air Purity Matters in Modern Surgery

Operating rooms are increasingly evaluated by outcomes and occupational safety, not only by particle count. In modular OR projects, the envelope is tighter and surfaces are more standardized—which supports infection control, but also makes gas-phase contaminants more noticeable if not engineered from day one.

A modern air-safety strategy must address three layers:

- ●Particles: microbes, dust, droplets (typically managed by HEPA + airflow).

- ●Gases/VOCs: chemical vapors, odors, anesthetic trace gases (managed by molecular filtration + dilution).

- ●Source emissions: plume, leaks, off-gassing (managed by capture + material control + sealing).

The Health Impact on Patients and Staff

VOCs and airborne chemicals can affect both patient safety and staff exposure, especially during long procedures or high turnover days.

- ●Patients: sensitive to residual chemical vapors; higher risk for vulnerable groups.

- ●Staff: repeated exposure may cause irritation, headaches, fatigue, or respiratory symptoms.

ISO 14644-1 vs. ISO 16000: What They Really Cover

ISO 14644-1: Particle Cleanliness (Not VOC Limits)

ISO 14644-1 classifies cleanrooms by particle concentration. It is essential for airborne cleanliness, but it does not define allowable VOC or anesthetic gas concentrations.

ISO 16000 Series: Testing Framework for VOCs

ISO 16000 provides methods for assessing indoor air quality, including VOC sampling and analysis. In hospital commissioning, it can be used as a reference framework for verifying gas-phase performance post-installation.

Main Sources of VOCs and Gases in Operating Rooms

1) Anesthetic Gases (Isoflurane, Sevoflurane)

Trace leakage can occur during mask induction, circuit disconnection, maintenance, or imperfect seals. Without proper scavenging, background concentration can rise—especially in high utilization rooms. This is why source capture (AGSS) is often prioritized before relying on dilution.

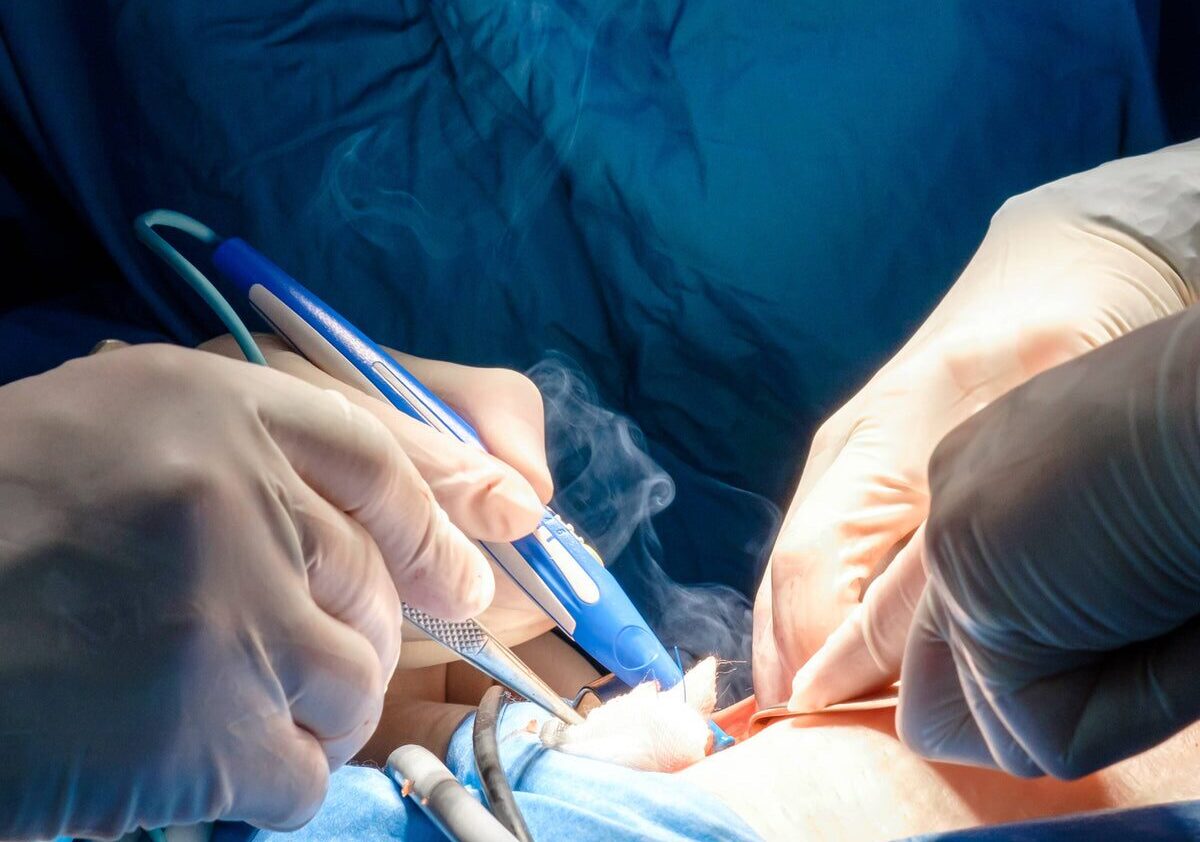

2) Surgical Plume (Electrocautery Smoke)

Plume contains ultrafine particles and gases. HEPA targets particles, but gas-phase toxins require additional control measures such as smoke evacuation and/or molecular filtration.

3) Chemical Off-gassing (Disinfectants + Materials)

Common contributors include aggressive disinfectants, sealants, adhesives, PVC products, and low-grade panel systems. In modular projects, selecting low-emission modular wall panels reduces baseline VOC load before ventilation even begins to dilute contaminants.

Control Methods: Filters, AGSS, and Air Strategy

Molecular Filtration: HEPA vs Activated Carbon

| Capability | HEPA | Activated Carbon |

|---|---|---|

| Particle / microbial control | ✅ Strong | ❌ Not designed for particles |

| VOC / odor reduction | ❌ Limited | ✅ Strong (depends on carbon type + contact time) |

| Trace anesthetic gas reduction | ❌ Limited | ✅ Helpful (as part of a system approach) |

| Typical placement | Supply terminal / AHU stage | AHU stage / recirculation / dedicated gas-phase module |

Source Capture: AGSS (Anesthetic Gas Scavenging System)

AGSS reduces background anesthetic gases by capturing waste gas at the source and routing it safely away from occupied areas. This is often the highest ROI measure for anesthesia-related gas control.

Air Exchange Strategy: Why the AHU matters

Filtration stages and gas-phase modules must be coordinated with AHU fan curves, airflow stability, and maintenance access. Proper operating room AHU selection determines whether carbon stages can be integrated without compromising laminar ceiling supply and pressure cascade.

Advanced ACH Strategy: Dilution, Velocity & System Stability

Air Changes per Hour (ACH) influence dilution rate, particle clearance, and thermal stability. However, ACH alone does not determine gas-phase safety. Effective VOC control depends on the relationship between:

- ●Air change rate (ACH)

- ●Airflow velocity (laminar dominance)

- ●Room pressure differential

- ●Carbon filtration contact time

ACH Comparison Table (Engineering View)

| Parameter | Standard OR | High-Performance Laminar OR | Engineering Consideration |

|---|---|---|---|

| Typical ACH | 20–25 ACH | 25–40 ACH | Higher ACH increases dilution but also increases energy load. |

| Supply Air Velocity | Mixed flow distribution | ~0.20–0.30 m/s laminar field | Laminar dominance improves particle displacement but does not eliminate gas accumulation without correct exhaust and source control. |

| Pressure Differential | +5 to +15 Pa (typ.) | +10 to +20 Pa (typ.) | Airtight envelope and a proven hospital hermetic door system are critical to maintain cascade integrity. |

| Gas Dilution Time | Moderate clearance | Faster clearance | Dilution efficiency depends on mixing pattern and exhaust placement. |

| Carbon Filter Contact Time | Often limited | Must be engineered | Gas removal efficiency depends on contact time between air and carbon media. |

Why ACH Alone Is Not Enough

Increasing ACH improves dilution mathematically. However, if:

- ●Leakage occurs through non-hermetic doors or penetrations

- ●Carbon stages are undersized or poorly accessible for maintenance

- ●Exhaust path is poorly positioned (stagnation zones)

- ●Anesthetic gases are not scavenged at source

then VOC accumulation may persist even at high ACH values.

Carbon Filtration Contact Time (Simple Explanation)

Activated carbon removes gases through adsorption. Performance is influenced by carbon bed thickness, air velocity through the media, and the time air remains in contact with the carbon. If airflow velocity is too high, adsorption efficiency drops.

Understanding Gas Dilution (Simplified Model)

Gas concentration reduction in a ventilated room can be approximated using an exponential decay model. In simplified terms, dilution performance depends primarily on ACH.

Basic Dilution Formula

The theoretical concentration over time can be expressed as:

- ●C(t) = concentration at time t

- ●C₀ = initial concentration

- ●ACH = air changes per hour

- ●t = time (hours)

This assumes ideal mixing. In real operating rooms, airflow pattern, exhaust placement, laminar dominance, and leakage significantly influence actual performance.

Low-Emission Modular Materials + Hermetic Sealing

Low-Emission Modular Wall Panels

A modular OR envelope should reduce hidden chemical load. Low-emission panel systems and factory-controlled bonding help limit on-site adhesives and uncontrolled curing. The result is typically faster commissioning and more stable IAQ.

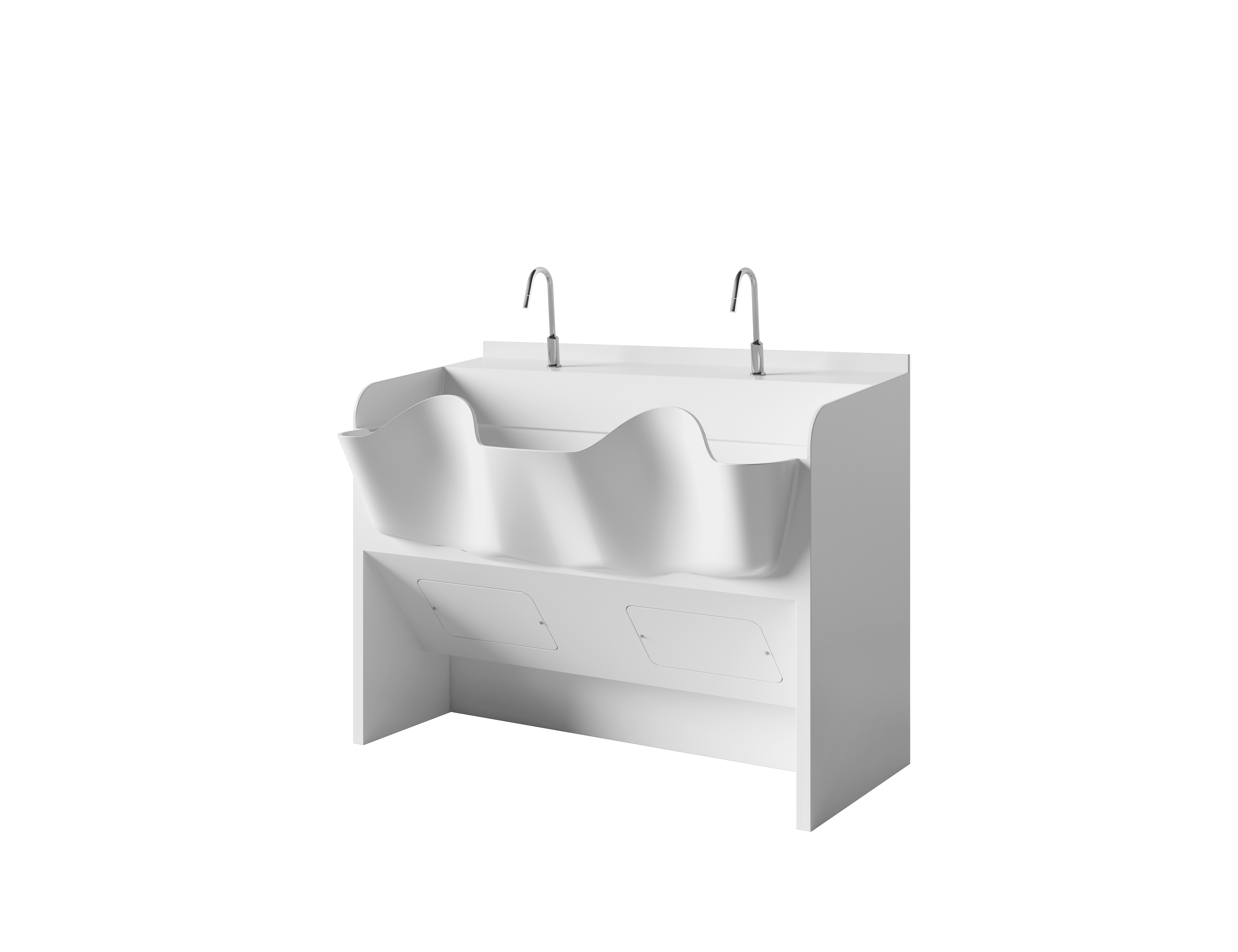

Hermetic Sealing: Keeping Pressure and Contaminants Under Control

Pressure integrity depends on a properly installed hermetic sliding door for operating rooms and seamless wall-to-frame integration. Airtight construction improves pressure stability and reduces infiltration, which supports both infection control and gas containment.

How contractors reduce VOC risk in modular OR delivery

Gas-phase issues often appear late—during commissioning. A smoother path is achieved when filtration stages, sealing details, and low-emission materials are aligned early in the design and submittal cycle. ICARELIFE typically supports contractors with coordinated packages across laminar ceiling, AHU interfaces, wall panels, and hermetic door sealing to reduce handover uncertainty—without complicating installation.

VOC Risk Assessment Checklist for Modular Operating Rooms

Before commissioning a modular operating room, contractors should evaluate potential VOC and gas-phase risks using a structured review.

1) Source Control Review

- ●Is an Anesthetic Gas Scavenging System (AGSS) specified and properly routed?

- ●Are surgical plume evacuation devices included where required?

- ●Are high-emission adhesives or sealants minimized?

- ●Are disinfectant protocols reviewed for chemical volatility?

2) Filtration & HVAC Coordination

- ●Is activated carbon filtration included for gas-phase control?

- ●Is carbon bed thickness adequate for contact time?

- ●Is AHU airflow balanced with laminar ceiling supply rate?

- ●Are exhaust locations positioned to prevent stagnation zones?

3) Airflow & Pressure Integrity

- ●Is the room maintaining required positive pressure (+Pa target)?

- ●Are hermetic doors tested for leakage?

- ●Are wall-to-ceiling interfaces properly sealed?

- ●Is ACH verified under operational load?

4) Material & Envelope Evaluation

- ●Are modular wall panels selected for low emissions?

- ●Is flooring material selected with low VOC rating?

- ●Are access panels and service penetrations airtight?

- ●Was curing time allowed before commissioning?

5) Commissioning & Verification

- ●Are airflow rates measured and documented?

- ●Are pressure differentials recorded under door cycling?

- ●Is filter installation verified?

- ●Is a VOC sampling approach defined (if required by project spec)?

Contractor Best Practice

Integrate VOC risk review during design coordination—not after installation. Early alignment between envelope, HVAC, and medical gas systems significantly reduces commissioning delays.

Future-Proofing Your Medical Infrastructure

VOC control is becoming a standard expectation in high-performance operating environments. Future-ready modular operating theater solutions are designed with:

- ●Molecular filtration provisions (carbon stages sized and accessible for maintenance)

- ●AGSS readiness and clear pipeline routing

- ●Balanced ACH strategy for dilution without instability

- ●Low-emission materials to reduce baseline VOC load

- ●Hermetic sealing details that protect pressure and performance

FAQ

Does ISO 14644-1 guarantee VOC safety in an operating room?

No. ISO 14644-1 addresses particle cleanliness. VOC and anesthetic gas concentration must be handled by gas-phase controls and verification methods.

Is higher ACH enough to control anesthetic gases and surgical plume?

ACH helps dilution, but it should not be the only control. Source capture (AGSS and smoke evacuation) plus molecular filtration is typically more effective.

What’s the difference between HEPA and activated carbon filtration?

HEPA targets particles. Activated carbon targets gases/VOCs and odors. High-performance OR systems often use both as complementary stages.

How can modular construction reduce VOC risk?

By using low-emission materials, factory-controlled lamination, reduced on-site adhesive use, and tighter sealing that stabilizes ventilation behavior.

What should contractors include in commissioning for VOC control?

Filter installation verification, sealing/pressure checks, airflow/ACH validation, AGSS functional checks (if applicable), and an agreed approach to VOC assessment where required.