Design Guidelines for HVAC Systems in Operation Theaters (OT)

Designing an HVAC system for an operation theater (OT) demands precision, expertise, and strict adherence to global healthcare standards. A properly designed system ensures patient safety, infection control, and operational efficiency.

This guide, based on ASHRAE 170, HTM 03-01, and CDC 2003/2005 standards, outlines the critical factors to consider when designing HVAC systems for operation theaters.

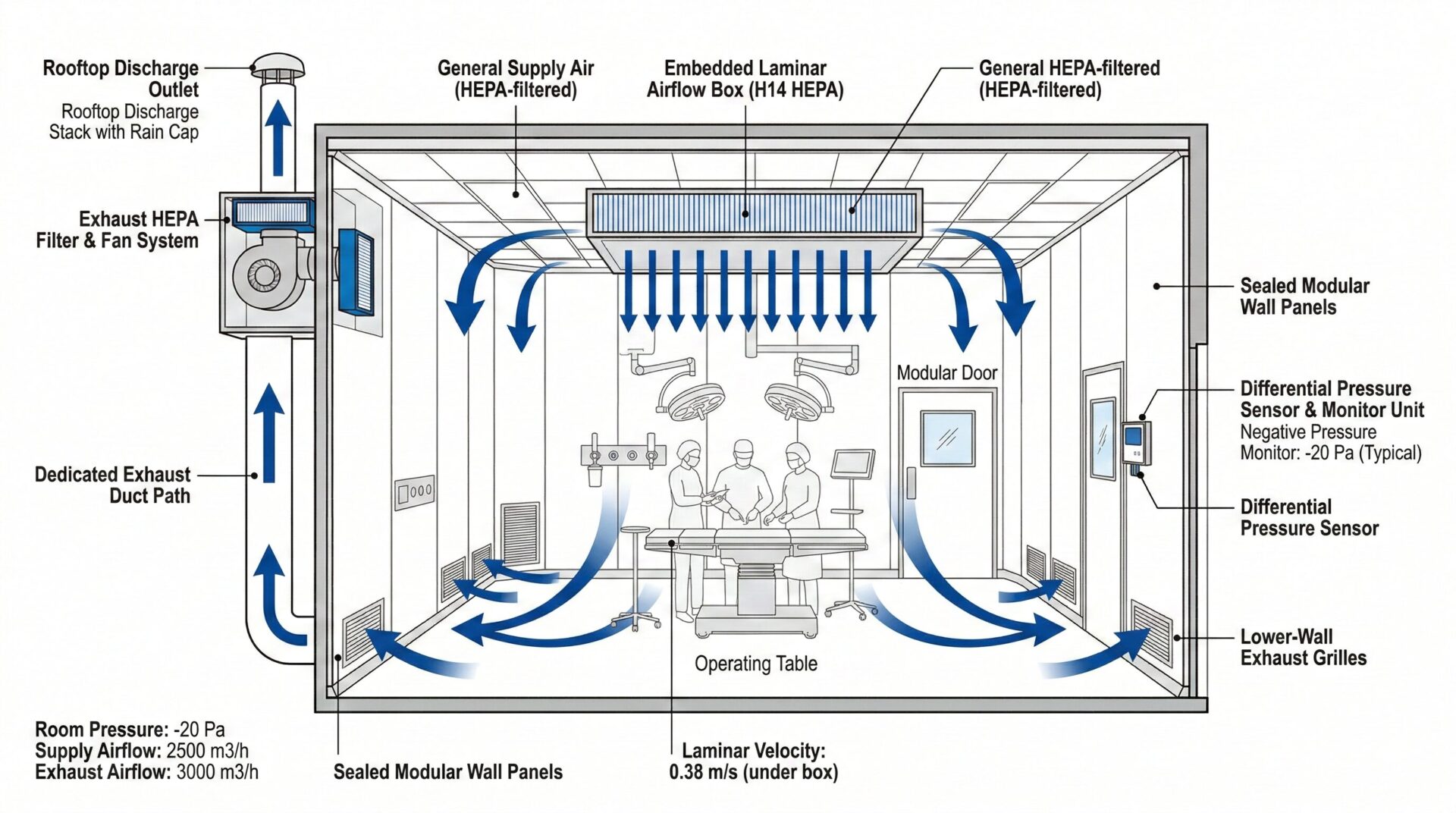

Why HVAC Design is Crucial for Operation Theaters

Operation theaters require a controlled environment with:

- Stable air temperature and humidity

- Effective filtration to reduce microbial load

- Controlled airflow patterns to protect the sterile field

- Positive pressure to prevent outside contaminants from entering

Following proper design guidelines ensures safety for both patients and surgical staff.

Standards for Operation Theater HVAC Systems

- ASHRAE 170: Ventilation standards for healthcare facilities

- HTM 03-01: UK healthcare technical standards

- CDC Guidelines: Infection control and ventilation requirements

Key Elements of Operation Theater HVAC Design

1. Operation Theater Types

- Super Speciality OT: Neuro, orthopedic, cardiac surgeries

- General OT: Common surgical procedures

- Day Care OT: Minor surgeries with quick discharge

Note: HVAC design principles remain consistent across OT types.

2. Load Calculations

Design must consider:

- Occupancy: 5–8 persons per theater

- Equipment Load: 5–7 kW

- Lighting Load: ~1 kW

- Ambient Temperature & Humidity: Location-specific adjustments

3. Air Changes per Hour (ACH)

| Air Type | Minimum ACH |

|---|---|

| Supply Air | 20 ACH |

| Fresh Air | 4 ACH |

Fresh and recirculated air is allowed. 100% fresh air is not mandatory except for special isolation OTs.

4. Air Velocity and Diffuser Selection

- Air Velocity: 25–35 FPM (Feet Per Minute)

- Diffuser Type: Non-aspirating laminar flow diffusers

- Material: SS304 stainless steel or aluminum

- Placement: One foot above the operating table

5. Positive Pressure Requirements

- Maintain a positive pressure of +2.5 Pascal compared to adjacent areas.

- Return air grilles should be installed 75–150 mm above the floor.

This ensures that clean air always moves outward, preventing contamination.

6. Filtration System

| Stage | Filter Type | Efficiency |

|---|---|---|

| Pre-Filter | MERV 7–9 | Moderate |

| Final Filter | MERV 14 | High |

| HEPA Filter | H13 or H14 | ≥99.97% @ 0.3 microns |

Use multi-stage filtration to ensure ultra-clean supply air.

7. Temperature and Humidity Control

| Operation Theater Type | Temperature | Relative Humidity |

|---|---|---|

| Standard OT | 27°C | 20–60% |

| Joint Replacement OT | 18°C | 20–60% |

Controlling temperature and humidity is vital for both patient comfort and infection control.

8. Outdoor Air Intake Precautions

- Ensure AHUs are placed where outdoor intakes are free from contaminated exhaust air.

- Avoid reintroducing polluted air into the OT ventilation system.

9. Regular Testing and Validation

Essential tests to perform every six months:

- Air change rate verification

- Temperature and humidity monitoring

- Particulate count testing

- HEPA filter integrity check

- Pressure differential verification

- Air velocity measurements

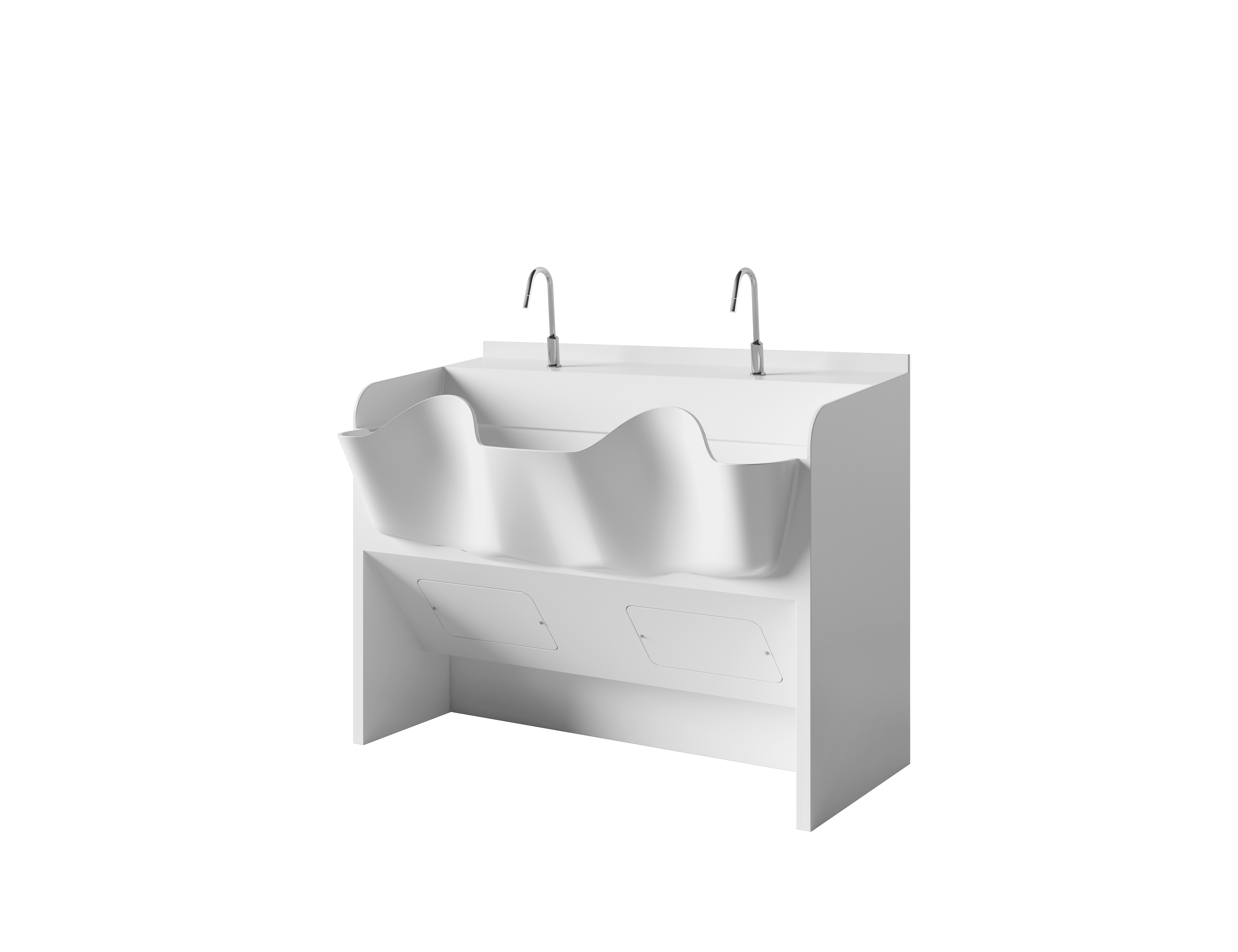

Best Practices for Operation Theater HVAC Systems

- Use a dedicated AHU exclusively for OTs.

- Avoid split AC units to prevent microbial growth.

- Paint OT interiors with antibacterial and antifungal coatings.

- Install cleanroom-grade lighting fixtures.

- Provide separate power circuits for sensitive equipment (e.g., lasers).

Conclusion

A meticulously designed HVAC system is the backbone of a functional and safe operation theater. By following ASHRAE 170 and other global standards, you can create a sterile, controlled environment that safeguards patients and ensures successful surgical outcomes.

For a successful OT project, always work with HVAC specialists familiar with healthcare compliance standards.

Frequently Asked Questions (FAQs)

What is the required air change rate for an operation theater?

According to ASHRAE 170, a minimum of 20 ACH (air changes per hour) for supply air and 4 ACH for fresh air is required for operation theaters.

Why is positive pressure important in operation theaters?

Positive pressure (at least +2.5 Pascal) prevents contaminated air from entering the sterile environment, protecting patients during surgical procedures.

What type of filters are used in operation theater HVAC systems?

Operation theaters use multi-stage filtration, including pre-filters (MERV 7–9), final filters (MERV 14), and HEPA filters (H13 or H14) to ensure ultra-clean air.

How often should HVAC systems in OTs be tested?

Critical performance tests, such as air velocity, pressure differential, particulate count, and HEPA filter integrity checks, should be carried out every six months.

Can split AC units be used in operation theaters?

No, split AC units are not recommended as they can promote microbial growth. Dedicated AHUs with proper filtration must be used for OTs.