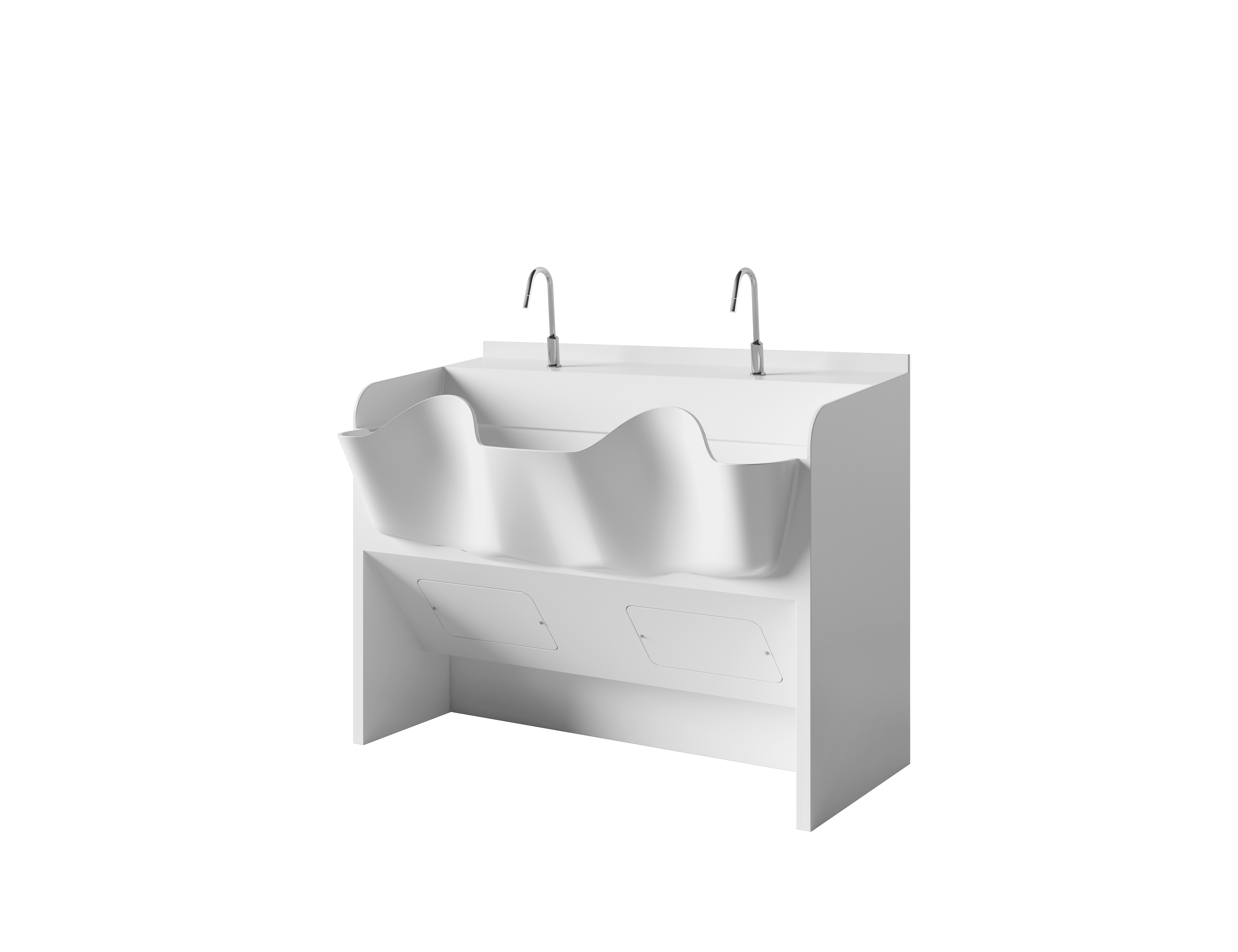

Surgical Scrub Sink Installation Guide

(Corian Solid Surface Material)

This guide applies to ICARELIFE solid-surface scrub sinks made from high-performance medical-grade materials, including Corian-type solid surface and other solid surface composites.

1. Purpose of the Installation Guide

This guide ensures ICARELIFE solid-surface scrub sinks—including models made with Corian-type solid surface and similar medical-grade composites—are installed safely, accurately, and efficiently in hospital cleanroom environments. All procedures follow ICARELIFE’s official installation standards.

2. Construction Interface Requirements

2.1 Floor Requirements

- The floor must be level (±5 mm tolerance) to ensure proper alignment of the solid-surface sink.

- Floor adhesive and finishing should be completed before installation.

2.2 Wall Requirements

- Walls must be smooth and structurally solid.

- Maximum deviation allowed: ±5 mm.

- Wall finishes must be complete before re-measurement.

2.3 Plumbing & Electrical Requirements

- Cold & hot water supply points with splash-proof sockets.

- Drain outlet positioned according to ICARELIFE drawings.

- Power socket (single or five-hole) installed to ICARELIFE MEP layout.

- Rough-in must be aligned with the purchased solid-surface (Corian-type) sink model.

2.4 Space Dimension Requirement

- Installation space must match the actual solid surface sink size.

- Leave maintenance/service clearance around the scrub sink.

3. Re-Measurement Procedure

3.1 Timing for Re-Measurement

- Conduct after floor and wall finishes are complete.

- Water and electrical points must already be installed.

3.2 Re-Measurement Scope

- Confirm MEP points match ICARELIFE’s structural diagram.

- Ensure no conflict with the solid-surface sink’s internal support frame.

- Verify transport path (elevator, corridors, doors).

- Record all values using the ICARELIFE Re-measurement Form.

3.3 Out-of-Tolerance Handling

- ICARELIFE sinks allow +3 mm positive tolerance.

- Contact ICARELIFE if deviation exceeds normal limits.

4. Transportation & Handling Guidelines

4.1 Personnel Requirement

- Single sink: 1–2 persons

- Double sink: 2–4 persons

- Triple sink: 4–6 persons

4.2 Tools Required

- Forklift (extended forks)

- Flatbed trolley

- Load straps

- Scissors, hammer

4.3 Transportation Steps

- Inspect packaging for moisture or damage.

- Keep sink upright during forklift/trolley movement.

- Transport mirror frame separately.

- Unload the solid-surface basin evenly on a flatbed.

- Move carefully through corridors.

- Dispose of packaging properly.

5. Installation Procedure

5.1 Required Tools

- Level, tape measure, pencil

- Impact drill, angle grinder

- Screwdrivers, wrench, cordless drill

- M6 hex key, sealing tape

- Glass glue & gun

- Sandpaper

- Voltage tester

5.2 Installation Steps

- Mark installation height; adjust wall edges if needed.

- Drill mounting holes; ensure no concealed pipes.

- Install mirror frame with M6 screws.

-

Wall-mount: Align with brackets and secure with expansion bolts.

Floor-mount: Raise basin 250 mm, align, drill, and anchor. - Connect angle valves, hot/cold hoses, and drain pipe.

- Install power socket; connect sensor and optional thermostatic valve.

- Install baseboard and adjust door panels.

- Apply medical-grade silicone at 45° to seal Corian-type solid surface to wall plane.

6. Special Installation Tips

- Confirm no concealed pipes exist before drilling.

- Avoid installing on hollow/non-load-bearing walls.

- Protect solid-surface (Corian-type) basin from debris and scratches.

7. Final Inspection & Acceptance

7.1 Contractor Self-Inspection

- Verify appearance of solid-surface basin.

- Confirm water and electrical systems.

- Check sensor, drain, and faucet operation.

7.2 ICARELIFE Acceptance Inspection

- ICARELIFE conducts final quality acceptance.

- Acceptance Form must be completed and signed.

About Our Solid Surface (Corian-Type) Material

ICARELIFE surgical scrub sinks are manufactured using high-performance solid-surface composites comparable to Corian-type materials. These solid surfaces offer seamless joints, antimicrobial performance, and long-term durability suitable for operating theatres, cleanrooms, and medical preparation areas. While ICARELIFE is not affiliated with the Corian® brand, our sinks are fully compatible with the same material class widely specified by architects and hospital design teams.

Seamless, Hygienic Surface

Corian-Type Composite Material

FAQ: Solid Surface & Corian-Type Materials

1. Is Corian solid surface suitable for hospital scrub sinks?

Yes. Corian-type solid surfaces are widely used in medical environments due to their seamless fabrication, high hygiene standards, and resistance to cleaning chemicals.

2. Does ICARELIFE use genuine Corian®?

ICARELIFE is not affiliated with the Corian® brand. Our scrub sinks use medical-grade, solid-surface composites comparable to the Corian-type material class, ensuring performance equal to or better than many branded solid surfaces.

3. What are the advantages of Corian-type solid surface compared to stainless steel?

Solid surface offers warmer aesthetics, seamless joints, higher customizability, and easier integration with modern OT interior design. Stainless steel is durable but more industrial-looking and less flexible for aesthetic OT environments.

4. Are solid surface scrub sinks easy to maintain?

Yes. The non-porous, seamless surface prevents bacterial growth and supports simple daily cleaning with standard hospital disinfectants.