Introduction

Modular operating theaters (MOTs) are revolutionizing surgical infrastructure across the globe. Unlike brick‑and‑mortar operating rooms, these suites are built using prefabricated modules in a factory environment and installed on site within weeks. The approach solves many of the challenges facing healthcare providers today: capacity shortages, infection control and rising construction costs. Reports show that hospitals increasingly adopt modular construction to speed up the delivery of new surgical spaces, enabling them to respond quickly to patient demand and reduce backlogs.

Why hospitals are choosing modular OTs

Time‑saving: A key advantage of modular construction is speed. According to ModuleCo Healthcare, off‑site construction can deliver a fully functional theater in a matter of weeks, with the entire project timeline less than half that of a conventional build (Four Reasons to Hire a Modular Operating Theatre). Rapid installation means healthcare providers can bring extra capacity online quickly and reduce the risk of delayed surgeries.

Quality guaranteed: Modern modular facilities are permanent, robust structures. They are designed, built and quality‑checked in controlled factory conditions, ensuring high build quality and compliance with strict healthcare standards (Four Reasons to Hire a Modular Operating Theatre). Seamless finishes, flush fittings and specialist coatings limit microbial growth and create a hygienic environment that is easier to maintain than traditional OTs.

Cost‑effective: Modular theaters can be more affordable than traditional builds. For public hospitals facing budget constraints, leasing or managed‑service agreements spread the cost over time, removing the need for large upfront capital investment (Four Reasons to Hire a Modular Operating Theatre). Prefabrication reduces waste and site disruption, while faster deployment allows hospitals to begin using the space sooner, generating revenue earlier. Some sources note that modular projects can deliver sterile, efficient facilities within a 36‑week timeline at a total cost of roughly US$760 000 to US$1.5 million, compared with higher costs and longer schedules for traditional construction (Modular vs Traditional Construction Costs for Hospitals).

Infection control built in

Preventing surgical site infections is a top priority for hospitals, and modular OTs are engineered with infection control at their core. Technomed explains that modular theaters use seamless anti‑bacterial wall panels made from stainless steel or high‑pressure laminates. These surfaces have no joints or gaps, making them easy to clean and resistant to microbes (Modular Operation Theaters Infection Control – Technomed). Materials meet cleanroom standards and withstand harsh disinfectants without degrading.

Airborne contamination is another major concern. In traditional operating rooms, poor air circulation and uncontrolled airflow can create microbe‑filled air pockets. In modular theaters, scientifically engineered HVAC systems deliver laminar airflow through HEPA or PTFE filters, ensuring a continuous flow of filtered air across the surgical field. Smart technology monitors air pressure, temperature, humidity and particulate count in real time to maintain safe conditions (Modular Operation Theaters Infection Control – Technomed). Some systems integrate UV‑C sterilization to disinfect the room between procedures, further reducing contamination risk (Modular Operation Theaters Infection Control – Technomed). The result is lower rates of surgical site infections and higher patient safety.

Long‑term value

Beyond infection control, modular OTs provide long‑term value to hospitals. The prefabricated nature of these suites means they can be expanded or reconfigured as clinical needs change. Modules can be relocated or upgraded without major downtime, supporting future‑proofing and scalability. Because the units use energy‑efficient LED lighting and advanced insulation, operating costs are lower than those of conventional rooms. Materials like Corian® solid surface and HPL wall panels are durable and easy to maintain, reducing lifecycle costs.

Hospitals also appreciate the minimal disruption during installation. While a conventional OT might take months to build and can interrupt ongoing surgeries, modular suites are assembled in a controlled factory and delivered as nearly finished units. Installation on site is fast, often taking days, and can be scheduled to minimize impact on clinical services. This efficiency translates to reduced downtime and fewer cancelled procedures.

Comparing modular and traditional OT costs

The cost of a modular operating theater depends on size, equipment and local construction factors. However, several studies suggest that modular solutions offer significant savings over traditional builds. The long‑term cost of modular glass wall systems can be up to 72 % lower over a 30‑year lifecycle compared with conventional construction, according to MBM Consulting (Role of Modular Operation Theaters | WMSPL Blogs). Another report from LinkedIn estimates that constructing a modular theatre can cost between US$760 000 and US$1.5 million and be completed in about 36 weeks (Operating theatre quality and prevention of surgical site …). These figures highlight the financial benefits of modular design: reduced labour costs, faster project completion and lower operational expenses.

Conclusion & next steps

Modular operating theaters combine innovation, quality and cost efficiency in a way that conventional construction cannot match. By leveraging prefabricated modules, hospitals can quickly expand surgical capacity, ensure high standards of hygiene and control costs. The integration of seamless antibacterial surfaces, advanced airflow systems and real‑time monitoring makes modular OTs a smart investment for healthcare providers striving for safety and excellence.

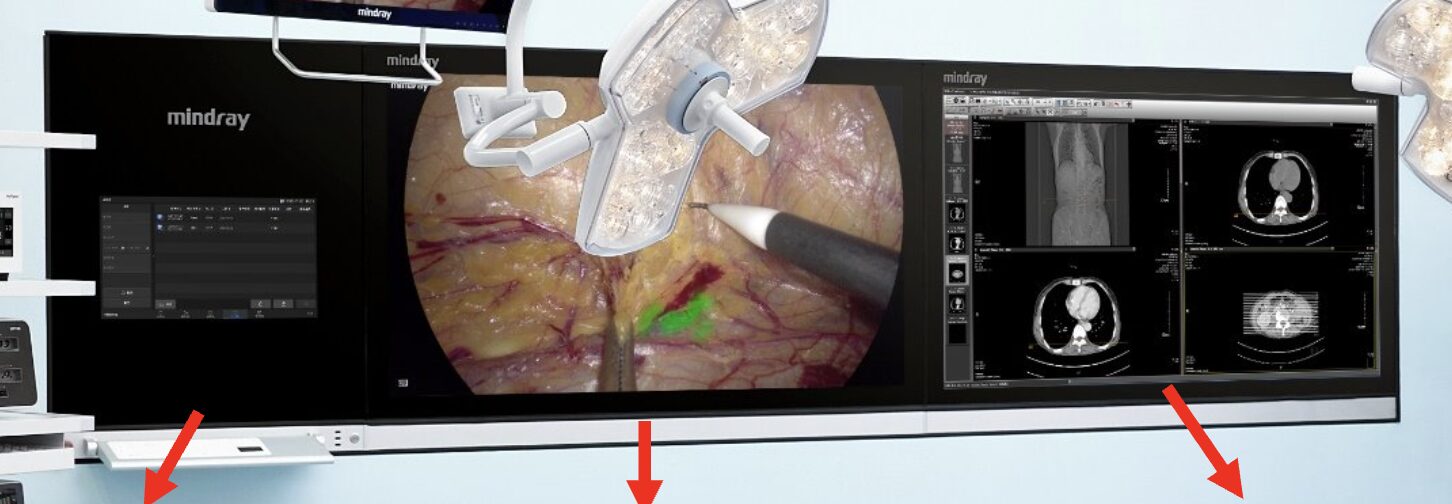

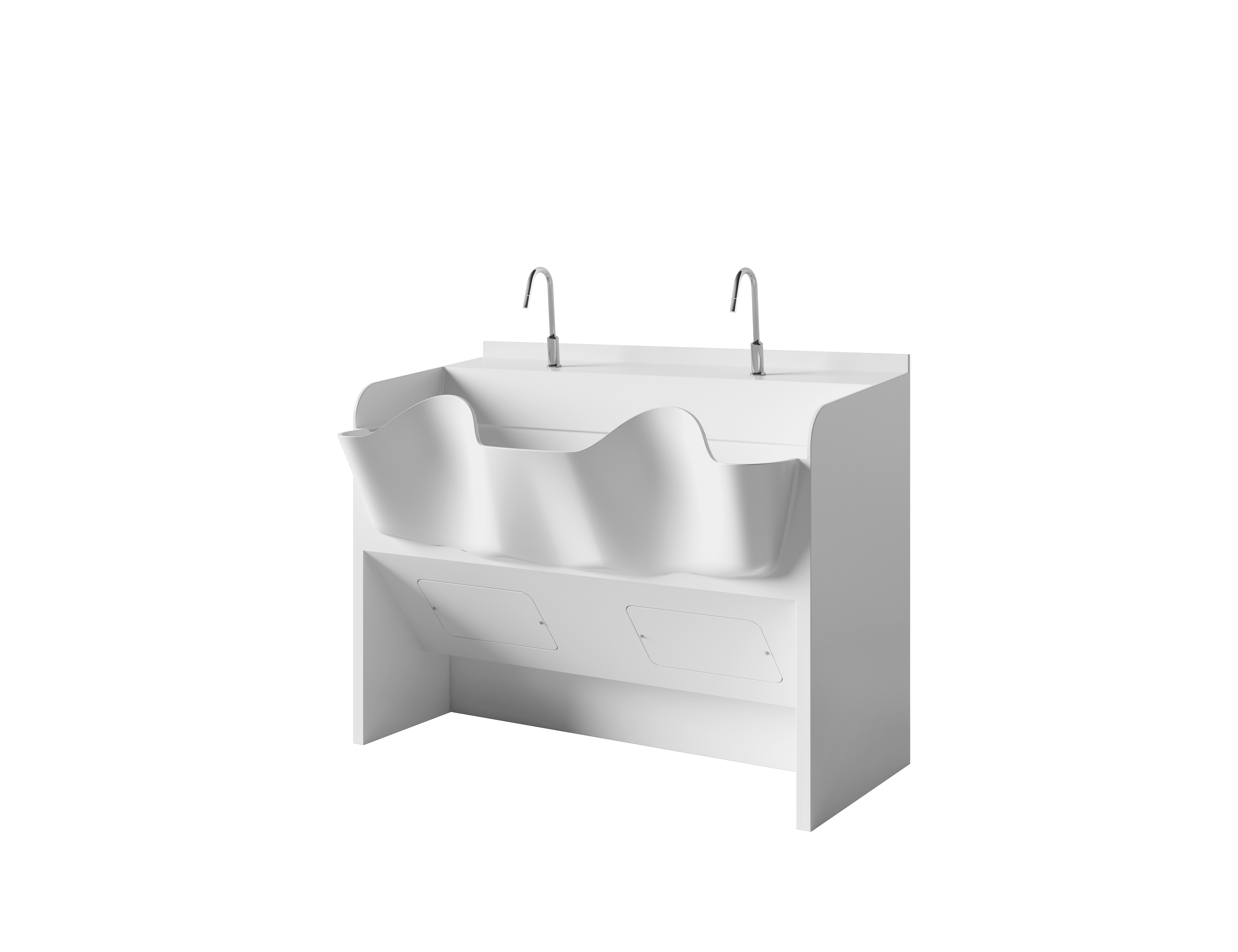

At ICARELIFE we specialize in designing, manufacturing and installing modular surgical suites that meet international standards. Our solutions include hermetic doors, laminar airflow ceilings, solid surface scrub sinks and other products that integrate seamlessly into your operating rooms. To learn more about how modular OTs can transform your facility, explore our product pages such as our Operating Room Wall Panel system or get in touch with our team for a consultation.

Ready to upgrade your surgical spaces? Contact us today to discuss a tailored modular OT solution that delivers performance, safety and value.