Understanding Laminar Airflow Ceiling Systems

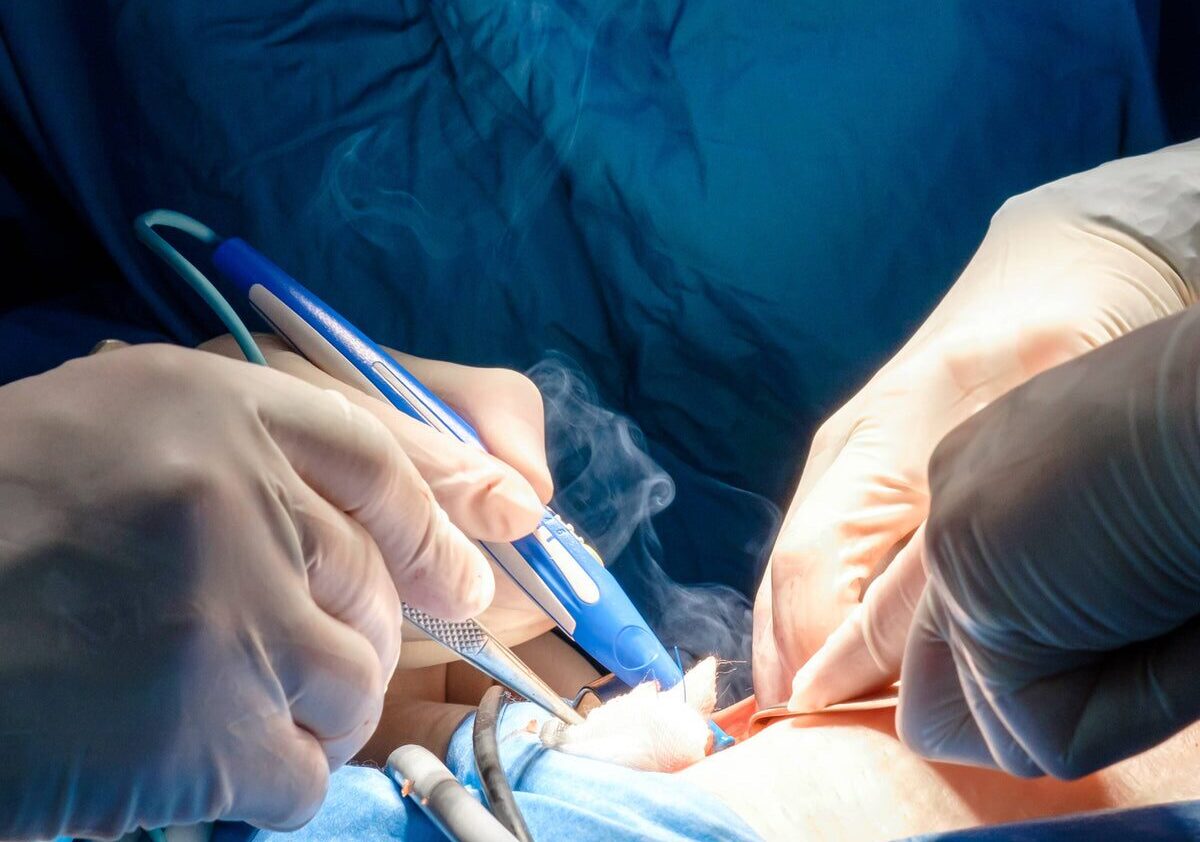

Laminar airflow ceiling systems play a crucial role in maintaining sterile environments, especially within operating rooms. These systems are designed to create a controlled air flow that significantly reduces the risk of airborne contamination during surgical procedures. By providing a consistent and unidirectional flow of air, laminar airflow ceiling systems effectively filter and direct clean air towards the surgical area, ensuring that particles that could compromise sterility are minimized.

The primary mechanism behind laminar airflow is the use of high-efficiency particulate air (HEPA) filters, which capture airborne contaminants, including bacteria and dust particles. The clean air is then pushed downwards in a smooth, uniform manner, preventing turbulence that can disturb these filtered particles. This meticulous design is vital for maintaining air quality in healthcare settings, as it directly impacts patient outcomes and infection control.

There are several configurations of laminar airflow systems utilized in healthcare settings, with the most common types being vertical and horizontal laminar airflow systems. Vertical systems operate by directing the air flow from the ceiling downwards towards the floor, while horizontal systems provide air flow from the sides of the operating room. Each configuration has unique benefits, and the choice of system often depends on the specific needs of the surgical procedures being performed as well as the room design.

In addition to their functionality in minimizing contamination, laminar airflow ceiling systems are also integral to the overall design of modern operating rooms. They ensure that all areas within the surgical space receive a consistent supply of filtered air. This results in an environment that is conducive to both surgical precision and patient safety, aligning with stringent infection control standards that healthcare facilities are required to uphold.

Cleanroom Classifications and Their Implications

Cleanroom environments are critical in operating room settings, where the need for contamination control is paramount. Cleanroom classifications are defined based on the maximum allowable particle counts in the air, with specific standards established by organizations such as the U.S. Federal Standard 209E. These classifications include categories like 10,000 (10k), 100,000 (100k), and 100 cleanrooms, each featuring distinct criteria and stringent requirements that influence the design and functionality of laminar airflow ceilings.

A Class 10,000 cleanroom permits no more than 10,000 particles per cubic meter of air, measuring ≥0.5 microns in size. This level of cleanliness is crucial for specific surgical procedures and environments requiring moderate control of particulate contamination. Laminar airflow ceilings in this classification employ high-efficiency particulate air (HEPA) filtration systems that blow filtered air in a uniform manner, reducing turbulence and assisting in maintaining operational standards critical to the success of the procedures conducted within.

On the other hand, a Class 100,000 cleanroom allows for a much higher particle count, thus demanding an airflow system that can effectively manage an increased risk of contamination. A surgical suite designed to meet this standard must incorporate advanced laminar airflow systems that not only provide consistent airflow but also optimize patient safety during operations. When operating in such environments, maintaining the sterility of instruments, surgical drapes, and the overall atmosphere is paramount to achieving favorable outcomes.

Lastly, a Class 100 cleanroom represents the highest standard for cleanliness, allowing no more than 100 particles per cubic meter of air. This classification is often standard in critical surgical operations, where even the slightest contamination could lead to severe complications. In these instances, laminar airflow ceilings play a vital role in generating a sterile environment through continuous, controlled air circulation, thereby ensuring the highest level of safety for both patients and medical personnel. Selection of the appropriate laminar airflow ceiling system becomes a critical factor in succeeding in such demanding environments.

Factors to Consider When Selecting a Laminar Airflow Ceiling

Choosing the appropriate laminar airflow ceiling for operating room environments requires a careful assessment of several critical factors. One of the primary considerations is the air changes per hour (ACH) required for the specific cleanroom classification. According to industry standards, operating rooms must achieve a certain level of air purification, often necessitating higher ACH rates to ensure optimal sterile conditions. Understanding the specific requirements for different clean class environments will aid in making an informed decision.

Another essential factor is the type of filters integrated into the laminar airflow system. High-Efficiency Particulate Air (HEPA) filters are commonly used in these systems as they can effectively capture airborne particles and contaminants. However, the choice of filter may vary based on the room’s intended use, and the level of filtration should align with compliance regulations outlined by health authorities. Investigating the filtration effectiveness and longevity can significantly impact operational efficiency and maintenance strategies.

The layout of the operating room also plays a crucial role in selecting a laminar airflow ceiling. Proper airflow distribution is necessary to minimize turbulence and prevent contamination during surgical procedures. Therefore, the design of the ceiling should facilitate a unidirectional flow that optimally covers the critical areas of the room, including the surgical site and surrounding zones. Additionally, compliance with regulatory standards is pivotal. Familiar awareness of accreditation guidelines, such as those from the American National Standards Institute (ANSI), ensures that the selected ceiling adheres to legal and safety protocols within healthcare environments.

Finally, it is vital to account for manufacturer specifications, maintenance requirements, and overall costs associated with the laminar airflow ceiling. Researching various manufacturers can provide insight into the long-term reliability and performance of these systems. Establishing a budget and understanding the ongoing maintenance needs will also affect the overall decision-making process, ensuring that the selection made serves the best interests of the healthcare facility.

Implementation and Maintenance of Laminar Airflow Ceilings

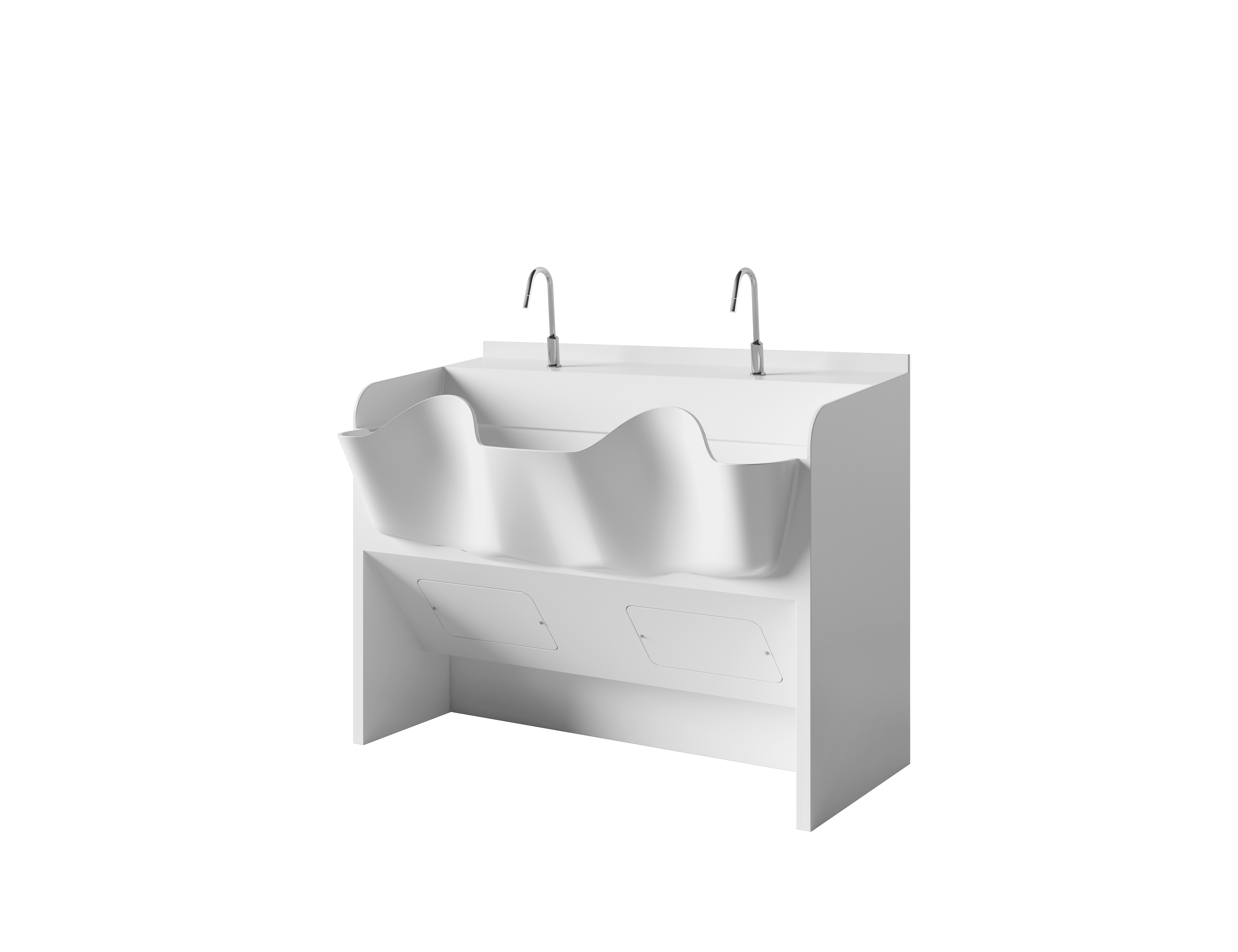

Implementing a laminar airflow ceiling in an operating room is a critical process that ensures a sterile environment necessary for surgical procedures. The installation of such systems requires careful planning, skilled personnel, and adherence to specific protocols to ensure that the airflow is consistent and effective. One of the first steps in installation involves assessing the room’s layout to determine the appropriate airflow distribution and ceiling configuration. Working closely with HVAC engineers and clinical staff can facilitate a smoother integration of the laminar air system into the existing infrastructure.

During the installation process, it is essential to use high-quality materials and components. Air supply diffusers, for instance, should be strategically placed to provide laminar airflow across the surgical field, minimizing the risk of airborne contaminants. Additionally, regular testing of the airflow pattern after installation helps confirm that the system operates as intended. Conducting airflow validation through methods such as particle counting and tracer gas testing ensures compliance with healthcare regulations and standards.

Ongoing maintenance is equally crucial for the optimal performance of laminar airflow ceilings. This involves routine inspections and maintenance schedules to clean filters and check mechanical components. An effective maintenance strategy includes replacing HEPA filters according to the manufacturer’s recommendations, typically every six months or sooner, depending on usage and environmental factors. Furthermore, calibration of airflow velocity should be conducted regularly to ensure precise airflow rates are maintained.

Challenges in the maintenance of laminar airflow systems may arise, such as filter clogging or mechanical failures. To address these issues effectively, preventive measures must be prioritized. Establishing a clear maintenance protocol and training staff on the system’s functionalities can facilitate proactive responses, thereby reducing operational disruptions. In conclusion, through proper implementation and vigilant maintenance, laminar airflow ceilings can significantly enhance the integrity of the sterile field in operating rooms, ultimately supporting better surgical outcomes.