Hygienic Coved Corners (Radius Trim R150/R300) in Medical Cleanrooms: Definition, Standards, and Cleanability Guide

Understanding how hygienic coved corners — also known as radius trims — eliminate 90° corners, improve infection control, and support ISO cleanroom hygiene. Includes a clear comparison between R150 and R300 curved profiles.

In medical cleanrooms and modular operating theaters, one architectural detail plays a surprisingly critical role in infection control: the hygienic coved corner. Also called a radius trim or internal radius corner, this curved profile replaces traditional 90° angles where walls meet ceilings, floors, or other walls.

International cleanroom standards — including ISO 14644, EU GMP Annex 1, and DIN 1946-4 — emphasize the need for surfaces that are seamless, smooth, and easy to clean. Coved corners directly support these requirements by eliminating contamination traps and allowing continuous wipe-down cleaning.

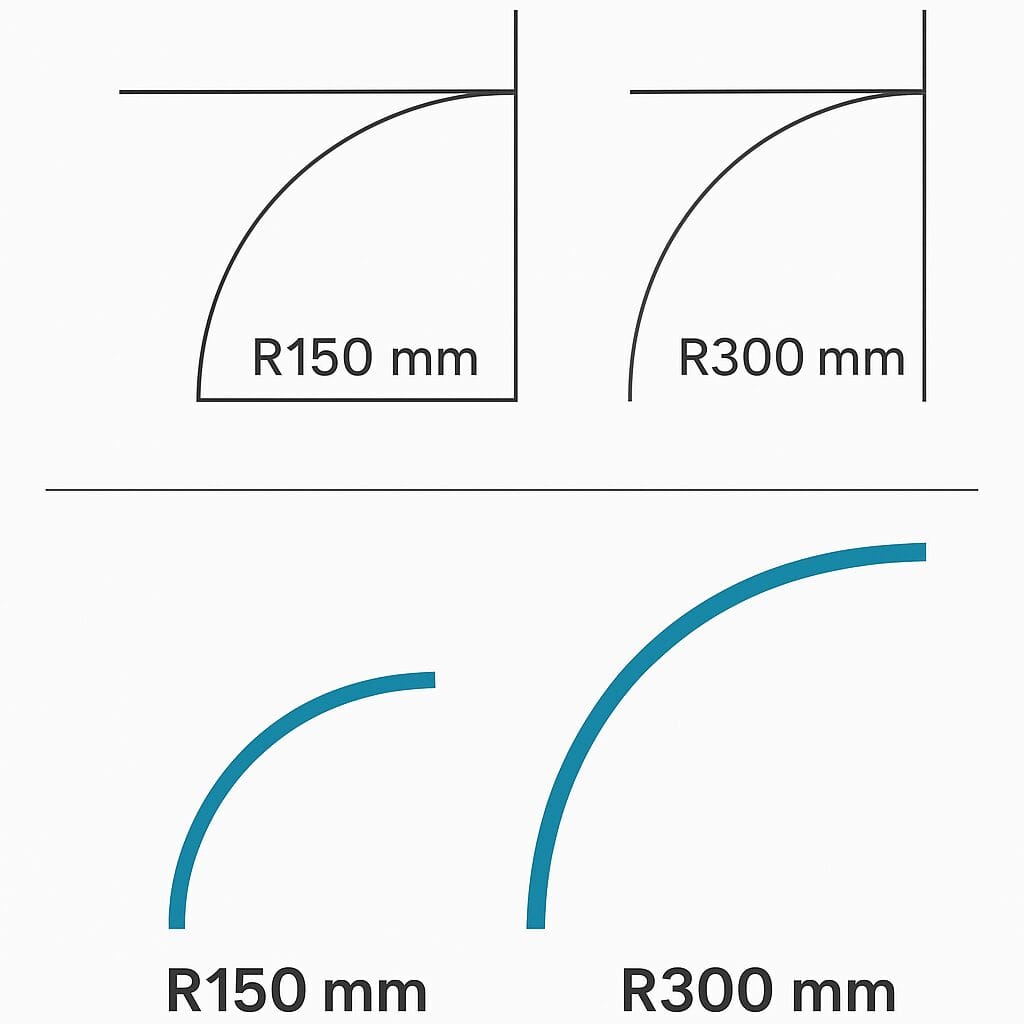

Coved corners come in different radii, typically R150 and R300, where the number indicates the curvature radius in millimeters. Selecting the appropriate radius affects hygiene performance, lifecycle maintenance, and overall cleanroom aesthetics.

What Is a Hygienic Coved Corner (Radius Trim)?

A hygienic coved corner is a smoothly curved transition used in the junctions of:

- Wall → Ceiling

- Wall → Floor

- Wall → Wall (internal corners)

This curve replaces the traditional 90° angle and provides several hygiene and operational benefits:

- Eliminates hard-to-clean internal corners

- Prevents dust, moisture, and microorganism buildup

- Allows rapid, continuous cleaning motions

- Supports ISO, GMP, and hospital hygiene standards

- Reduces cracking and silicone failures at joints

In many international specifications, this element is referred to as a:

- Coved Corner

- Hygienic Coving

- Internal Radius Corner

- Hygienic Radius Trim

“Radius Trim” is widely used in Asia and among modular OT manufacturers, while “Coved Corner” is the preferred term in Europe and international cleanroom standards.

Why Sharp Corners Are Not Suitable for Cleanrooms

Conventional 90° corners create hygiene challenges, particularly in sterile environments like operating rooms. Sharp corners:

- Capture dust and biological contaminants

- Retain moisture and cleaning chemicals

- Are difficult to disinfect thoroughly

- Suffer from silicone breakdown and cracking over time

A hygienic coved corner solves these issues by creating a smooth curve that allows effortless cleaning and stronger structural integrity.

How Hygienic Coved Corners Improve Cleanroom Performance

A curved internal radius enhances the cleanroom environment by:

- Allowing wipe-down cleaning in a single smooth motion

- Reducing airflow turbulence under laminar airflow ceilings

- Strengthening modular panel edges and corner transitions

- Improving long-term durability of joints and sealants

What Do R150 and R300 Mean?

In engineering and architectural drawings:

- R = Radius

- 150 / 300 = Radius size in millimeters

Therefore:

- R150 = 150 mm curved radius

- R300 = 300 mm curved radius

The larger the radius, the smoother and more hygienic the corner transition becomes.

R150 vs R300: Visual Comparison

The following diagram shows how R150 and R300 differ in curvature. A wider radius (R300) offers a smoother, more continuous cleaning surface.

Selecting the Correct Radius Size for Medical Cleanrooms

R150 (150 mm Radius)

- Compact curved profile

- Suitable for small spaces

- Ideal for ISO 7–8 cleanrooms and standard ORs

- Cost-effective option

R300 (300 mm Radius)

- Smoother, wider curvature

- Superior cleanability

- Preferred in premium operating theaters

- Offers better airflow stability

Many European projects — especially those following DIN 1946-4 — prefer larger radius coving for improved hygiene compliance.

Benefits of Hygienic Coved Corners

- Improved Hygiene — eliminates contamination traps

- Regulatory Compliance — aligns with ISO 14644, GMP, EU Annex 1

- Durability — reduces edge cracking and sealant failures

- Optimized Airflow — stabilizes laminar airflow patterns

- Modern Appearance — creates smooth, seamless interior surfaces

Terminology Across International Standards

| Region / Standard | Common Term Used |

|---|---|

| ISO 14644 | Coved Corner, Internal Radius |

| EU GMP Annex 1 | Coving, Radius Junction |

| DIN 1946-4 | Radius Corner, Hygienic Radius |

| UK HTM (Health Technical Memoranda) | Internal Radius, Hygienic Cove |

| Asia (China/India) | Radius Trim |

This table helps international contractors understand that “radius trim” and “coved corner” refer to the same architectural solution.

ICARELIFE Hygienic Coved Corner System

ICARELIFE provides both R150 and R300 hygienic coved corner systems, engineered to integrate seamlessly with:

Our radius profiles are available in aluminum alloy or SUS304 stainless steel, with optional antimicrobial coatings for high-demand hospital environments.

Conclusion

Whether you call it a hygienic coved corner, radius trim, or internal radius profile, this curved detail is essential for hospital infection control. By removing sharp corners and creating a seamless transition, these profiles play a major role in cleanability, airflow performance, and regulatory compliance.

Choosing between R150 and R300 depends on your room size, project standards, and hygiene expectations — but both significantly enhance cleanroom performance and support ICARELIFE’s mission to build spaces that heal.

- ISO 14644 – requires easy-to-clean junctions

- EU GMP Annex 1 – requires rounded internal corners (“coving”)

- DIN 1946-4 – recommends radius transitions in hospital ORs

- R150 = 150 mm radius

- R300 = 300 mm radius

R300 is recommended for premium operating theaters, ISO 5–7 environments, and regions following DIN 1946-4. European projects commonly request R300 for improved hygiene and effortless wipe-down cleaning.

- High-strength aluminum alloy

- SUS304 stainless steel

- Optional antimicrobial coating

Need Engineering Guidance for R150 or R300 Radius Selection?

ICARELIFE supports hospital contractors, cleanroom builders, and OT engineers with design advice, panel integration drawings, and complete modular operating theater solutions — including wall panels, radius trims, hermetic doors, laminar ceilings, and control panels.

✔ Free technical consultation

✔ Drawing review for your project

✔ Recommended radius selection based on ISO/DIN hygiene requirements